Graphics Reference

In-Depth Information

3D printers can also work with another category of plastics, soft plastics,

known as

elastomers

. Like their name suggests, these rubber-band-like materi-

als have various elastic properties. Some of these materials, like silicone, can

be squeezed through a syringe and then air-dried. Other soft, rubbery objects

can be printed by melting a thermoplastic elastomer, similar to the process

used to fabricate hard plastic.

In the early days of 3D printing, skeptics dismissed the new technology as

one that had no place among “real” manufacturing machines. Why? Because

in those days 3D printers could not manufacture metal parts. Now 3D printers

can print steel, titanium, and even tungsten—hard metals that are dificult to

shape using conventional manufacturing processes.

Printed metal machine parts are a popular industrial application for 3D

metal printing. Several metal printing methods are possible. One method

uses a multistep process in which metal powder is irst coated with a heat-

sensitive plastic binder and then selectively fused together with a laser. Next,

unfused powder is shaken off and the remaining metal object is placed into

a hot furnace where the plastic glue binder burns off. More direct methods

to print metal involve using jets to extrude molten metal or fusing raw metal

powder directly with a laser.

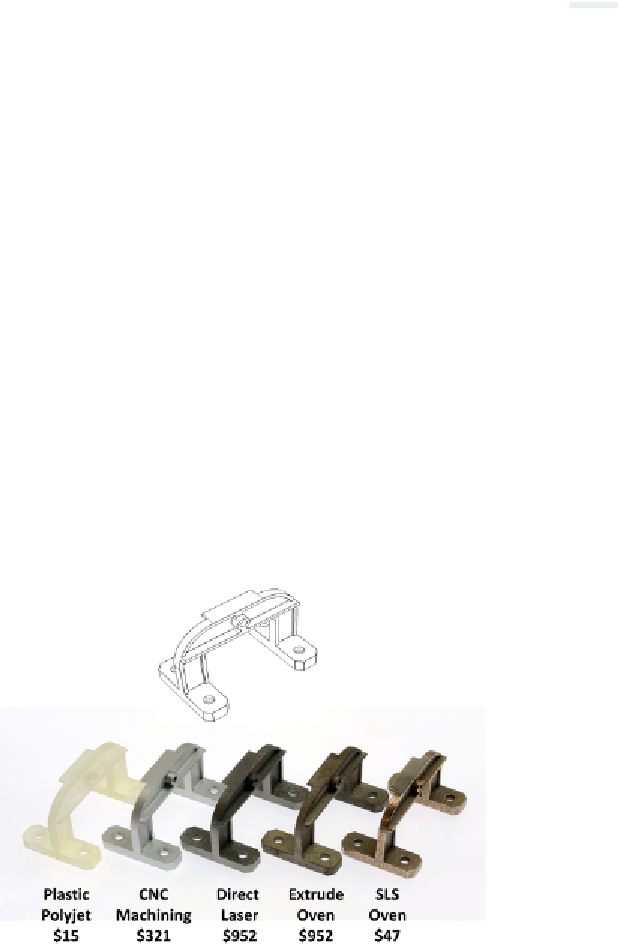

Design blueprint (top) and fabricated parts (bottom) using a

variety of methods and their actual costs