Environmental Engineering Reference

In-Depth Information

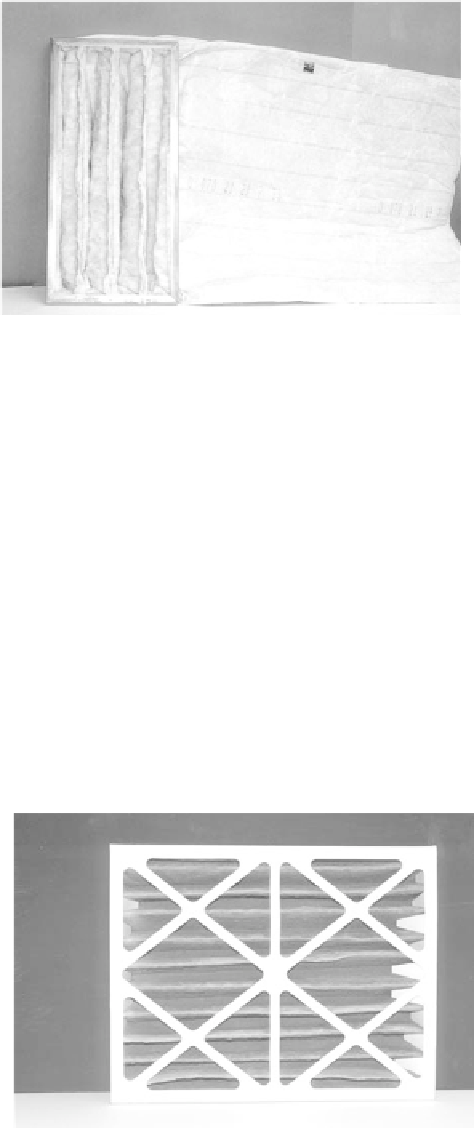

Figure 12.6

Bag-type filter.

face area of the filter). Pleat depth may be several inches to upwards of 12

to 18” (30.4 to 45.7 cm) or more. As the medium surface area is increased,

pressure drop decreases to acceptable levels (despite the increase in medium

density and/or thickness).

Extended-media filters vary in thickness, density, fiber size, media com-

position, pleats per nominal face area, and depth. As such, their performance

varies from medium to high efficiency. Cellulose, glass fiber, wool felt, or a

variety of synthetic fibers are used in extended-media filters. Fibers are

typically oriented randomly to form a mat.

Extended-media filters are available in several designs. They may be

constructed in the form of bags which are similar in concept, and somewhat

similar in design, to bags used in industrial applications. A bag-type

extended-media filter used in HVAC systems is pictured in

Figure 12.6

.

In typical pleated filters, the medium is held in place by a panel frame

or box (

Figure 12.7

)

. The V-shaped pleats may have a depth of 2 to 36” (5.1

Figure 12.7

Medium efficiency pleated-panel filter.