Environmental Engineering Reference

In-Depth Information

100

Im

+

In

+

D

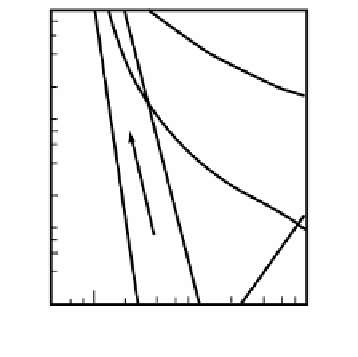

Impaction

Impaction +

Interception

10

Diffusion

Interception

1.0

Diffusion +

Interception

Interception

+ Gravity

0.1 1.0 10

Particle Diameter (

µ

m)

Figure 12.2

Relationship between particle size and deposition processes. (From

Hinds, W.C.,

Aerosol Technology — Properties, Behavior, and Measurement of Airborne

Particles,

John Wiley & Sons, New York, 1982. With permission.)

As can be seen in Equation 12.1, the ability of a particle to penetrate a

filter decreases exponentially with increasing filter thickness.

P = e

-rt

(12.1)

where P = penetration, %

e = natural log base

r = fractional capture per unit thickness

t = filter thickness, mm

The value of r depends on particle diameter, packing density, fiber density,

and face velocity of the airstream.

Not surprisingly, easy-to-collect particles are collected on or near the

surface of a filter. As particles move through it, particle size distribution

changes (based on aerodynamic diameters). Each filter type is characterized

by a particle size, usually between 0.05 and 0.5

m, at which fractional

collection efficiencies are minimal. This generalized relationship can be seen

in

Figure 12.3

for particles moving through a filter at 1 and 10 cm/sec. As

face velocity increases, a minimum value for collection efficiency is reached.

Collection due to diffusion at this point is at a minimum. These minimum

collection efficiencies are used to specify the performance of high-efficiency

filters. High-efficiency particulate absolute (HEPA) filters are reported to be

99.97% efficient at 0.3

µ

m. This means that they have a minimum 99.97%

collection efficiency for the most difficult-to-collect particle size.

Collection efficiency is also a function of fiber diameter (

Figure 12.4

)

.

The highest minimum collection efficiency and overall collection efficiency

occur at the smallest fiber diameter tested (0.5

µ

µ

m).