Environmental Engineering Reference

In-Depth Information

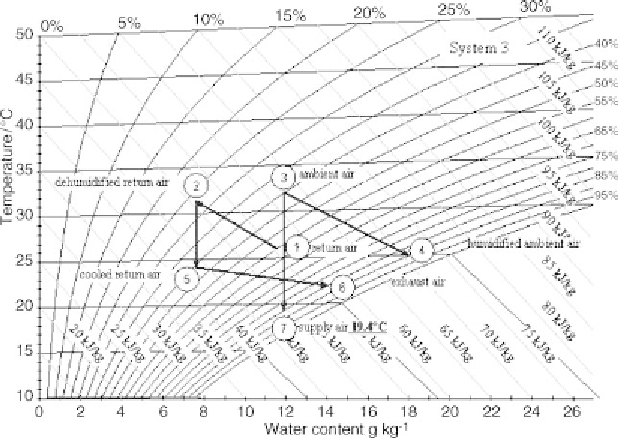

Figure 5.70

Supply air cooling of system 3 with the contact matrix absorber unit followed by two

spray humidifier heat exchangers

The adsorption wheel reached 19.6

◦

C in system 2 (Figure 5.71). The adsorption

wheel was regenerated at an air temperature of 70

◦

Cwith 12 g kg

−

1

absolute humidity

and a volume flow of 185m

3

h

−

1

. Path 1-2 describes the dehumidification of return

air in AWheel, path 3-4 the humidification of ambient air in the HES, path 2-5 the

cooling of return air in the HES, path 5-6 the humidification of return air in the HES

and path 3-7 the cooling of the supply air in the second HES.

The simplest supply air cooling in system 1, with just one water-sprayed HES,

reaches a supply air temperature of 22

◦

C (Figure 5.72). Path 1-2 shows the humidi-

fication of return air in the HES and path 3-4 the cooling supply air in the HES. This

process can be described as an isenthalpic humidification followed by heating and

humidification at constant relative humidity.

However, the essential advantage of the HEAU over the other two desiccant systems

is the combination of the absorber, the heat exchanger and the humidifier in one single

unit. This allows a very compact construction of the intended air-conditioning system

for residential buildings. Furthermore, the liquid desiccant systems offer the possibility

of loss-free storage of the concentrated solution, which enables the systems to produce

the cooling performance independently of the actual solar irradiation and therefore

avoids the necessity of an extra heating device for regeneration.

For the given design conditions of 200m

3

h

−

1

volume flow, a maximum of 886W

cooling power can be achieved using the most integrated system 4. The results for

the summer design conditions of 32

◦

C, 40% relative humidity outside air, and 26

◦

C,

55% relative humidity room air, are summarized in Table 5.8.

Search WWH ::

Custom Search