Environmental Engineering Reference

In-Depth Information

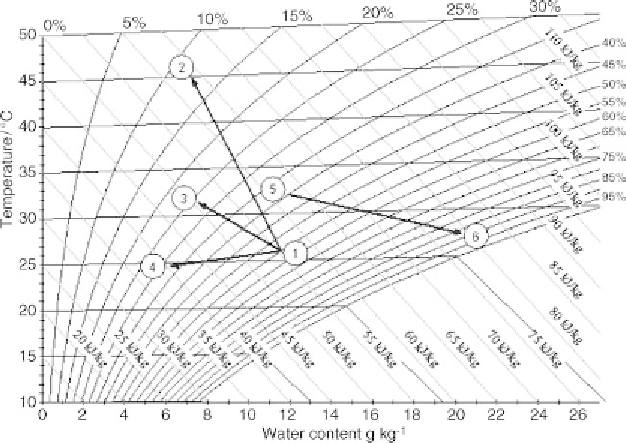

Figure 5.68

Paths of return air dehumidification for different process options

32

◦

C and 40% relative humidity. The results of the measurements taken at an air

volume flow of 200m

3

h

−

1

are shown in Figure 5.68.

Path 1-2 describes the measured dehumidification process in the investigated des-

iccant rotor (AWheel) using regeneration air with a 12 g

water

kg

−

1

air

humidity ratio, at

70

◦

C and volume flows of 187m

3

h

−

1

. The humidity of the return air is reduced in the

desiccant rotor by about 4.3 g

water

kg

−

1

air

, while the temperature of the return air is in-

creased by about 19

◦

C. This significant rise in temperature results from the adsorption

enthalpy and the heat transferred from the regeneration side.

Path 1-3, which indicates the dehumidification of the return air in the contact matrix

absorber unit (CMAU), shows a dehumidification of about 4.2 g

water

kg

−

1

air

combined

with an increase in the return air temperature of about 5

◦

C. A part of the absorp-

tion enthalpy is removed by the liquid desiccant so that the process also reduces the

enthalpy.

Path 1-4 shows themeasured dehumidification of the return air in the heat exchanger

absorber unit (HEAU). The humidity is reduced by about 5.7 g

water

kg

−

1

air

, while the

temperature of the return air is decreased by about 1

◦

C, that is, the process is just

slightly better than isothermal.

Path 5-6 shows the humidification and evaporative cooling process of the ambient

air in the cooling channels of the heat exchanger absorber unit. The humidification

process is also not isenthalpic. This is a consequence of the simultaneous removal of

Search WWH ::

Custom Search