Environmental Engineering Reference

In-Depth Information

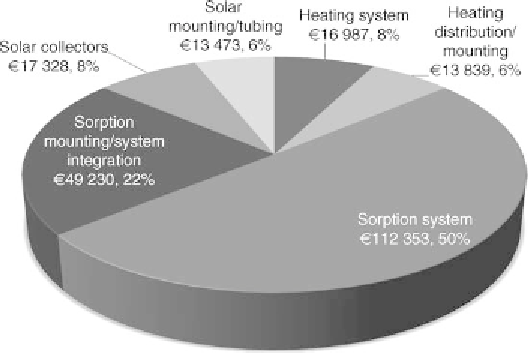

Figure 5.44

Total investment costs for hardware, tubing and system integration for the solar-powered

desiccant cooling plant in Althengstett with 18 000 m

3

h

−

1

volume flow

for the unit control and its connection to the existing building management system.

The collectors were responsible for 12% of the total investment costs, but mounting

and system integration were expensive at 15%. In total the price per cubic metre and

hour of air flow was similar to the German system at

D

15 per m

3

h

−

1

.

From the total investment costs in the Maier factory project, an annuity of

D

26 070

capital-related costs results. If the funding for the DEC investment costs of

D

100 000

is taken into account, the annuity reduces to

D

14 122. Consumption-related costs for

heat, electricity and water occur together with the demand charge to provide a given

electrical power. In total the annual consumption costs for the desiccant cooling system

were calculated at

D

3147, about 40% less than for a conventional air-conditioning

system (see Figure 5.45). In the Spanish Mataro project, the savings calculated from

electrical peak power cost reduction were

D

4200 per year.

In addition, operation-related costs for maintenance and repair arise. Repair costs

are usually between 1 and 3% of investment costs, so for the calculations, 2% was

chosen. Maintenance costs are in a similar range: 76% of the total annual costs are

capital costs, the rest are operation and consumption costs (see Figure 5.46).

The annual heating energy saving through the solar thermal collector field of about

D

1500 can be subtracted from the total annual costs. The remaining cooling costs for the

investigated year with 34 710 kWh of cold production result in a specific cold price of

D

0.94 per kWh without funding and

D

0.6 per kWh including the investment funding.

By comparison, the costs for a conventional air handling unit with humidification and

an electrical compression chiller were calculated in this project at

D

0.65 per kWh.

The high price per kilowatt hour is largely due to the low total cooling demand in

the building. At a nominal power of the system of approximately 100 kW, the cooling

Search WWH ::

Custom Search