Environmental Engineering Reference

In-Depth Information

(enthalpy of the supply air with isenthalpic dehumidification). Although both depend

on temperature and absolute humidity, the equations cannot be solved analytically and

the final state must be iterated. For this the absolute water vapour content of the supply

air

x

o

is reduced until the final state corresponds to the given humidity condition of

the regeneration air. The new temperature and relative humidity values are determined

after each dehumidifying step, until supply air humidity and regeneration humidity

correspond. Since the contact time of the air within the channels of the sorption rotor is

short and the sorption material is limited, the minimum value of the supply air humid-

ity with a vapour content

x

dry

ideal

is not achieved in practice. Non-ideal dehumidifying

at an effective supply air humidity value

x

dry

eff

is covered by the dehumidification

efficiency

η

dh

x

eff

x

o

−

dry

x

o

−

x

ideal

η

dh

=

dry

=

x

o

−

η

dh

x

o

−

x

ideal

x

eff

(5.4)

dry

dry

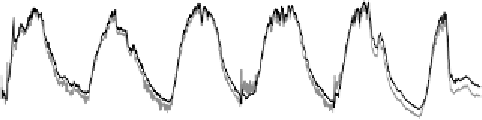

The best fit to the experimental data was obtained for a dehumidifcation efficiency

of 80%. Measured and simulated temperature levels after the sorption wheel (sup-

ply side) coincide very well, which shows the suitability of the simple model (see

Figure 5.39).

The component parameters from the experimental analysis of the two desiccant

cooling units in Spain and Germany are summarized in Table 5.3.

The system model includes the preheating of the regeneration air using the factory

waste heat. Mixing of the maximum collector volume flow of 6000m

3

h

−

1

and the

air, which is only preheated, takes place in the regeneration air stream before entering

the desiccant cooling unit.

60

Regeneration

55

50

45

SW out measured

40

35

SW out simulated

30

25

20

15

SW in

10

23

24

25

26

27

28

Date in July

Figure 5.39

Measured and simulated temperature levels after dehumidification by the sorption wheel

(SW) on the supply air side together with inlet and regeneration temperatures

Search WWH ::

Custom Search