Agriculture Reference

In-Depth Information

Recording dough mixers

A recording dough mixer (RDM) is truly the

workhorse of wheat science and technology and

provides the basis of a variety of standard methods

(e.g., AACC approved methods 54-21, 54-40A,

and 54-50, AACC 2000). The importance of

RDMs becomes more apparent when considering

that subsequent testing of developed doughs

requires a known and repeatable processing

history. This is most easily achieved with a RDM.

There are a number of RDMs in common use but

importantly they share elements of data output

and so the general features of RDMs can be

addressed as a whole rather than mixer by mixer.

This is despite the circumstance that the various

RDMs possess different mixing geometries (e.g.,

z-arm versus planetary pin), different minutiae

related to operation, differences in the precise

nature of their outputs, and limitations that are

unique to each type.

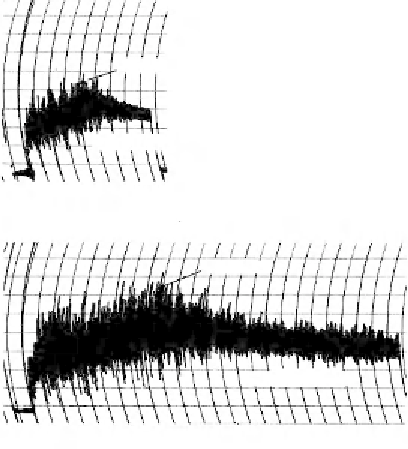

Using a mixograph (National Mfg. Co.,

Lincoln, Nebraska) trace as the archetype one can

observe the common elements (Fig. 20.4). Data

output can be analogue and read manually, but

most RDMs have the capacity to give electronic

outputs where the major descriptors of the mixing

curves are available through machine analyses. An

alternative method of assessing mixograms is by

visually scoring the overall shape of the mixogram

curve to provide a mixing tolerance score based

on comparison with a set of reference mixogram

curves (e.g., Baenziger et al., 2001).

The RDM curve can be partitioned into two

major portions: (i) a rising portion of the curve

prior to the peak where the fl our is hydrating and

dough development is occurring; (ii) a descending

portion where the developed dough breaks down

to a greater or lesser extent as a result of contin-

ued mixing (overmixing). Differences in the time

of arrival at peak development are indicative of

differences in mixing times that in a broad sense

are refl ected in mix times in commercial produc-

tion; elements of scale, geometry, and mixing

intensity change from mixer to mixer and these

aspects will dictate optimum mixing time in a

specifi c mixer.

For a given mixer faster arrival at peak dough

development can indicate faster hydration.

Hydration speed can affect mix times in both z-

arm and pin mixers. For example, Sapirstein et

al. (2007) showed that reducing the particle size

in a mix of durum semolina and fl our (by infer-

ence, increasing surface area to volume ratio of

the particles and therefore increasing hydration

rate) shortened development time in both the

farinograph and mixograph. Faster arrival at

peak dough development in a general sense can

also be related to weaker dough characteristics,

as short mix times are often but not always asso-

ciated with lower tolerances to overmixing. The

mixers themselves vary in mixing intensity and a

planetary pin-mixer like the mixograph has a

higher rate of energy input (more intense mixing

characteristics) than the available z-arm (e.g.,

farinograph) or blade mixers when these are run

at standard speeds. For example, it is known that

the amount of SDS-insoluble glutenin decreases

as mixing continues to peak development (Don

et al., 2003). Following from that Surel et al.

(2006) compared three RDMs and showed that

Peak Time

Mixing Tolerance

Weak Gluten Flour

Peak Time

Mixing Tolerance

Strong Gluten Flour

Fig. 20.4

Mixograms of typical weak (upper panel) and

strong (lower panel) doughs. [

Source

: Wheat Marketing

Center (2004).]