Agriculture Reference

In-Depth Information

can Association of Cereal Chemists developed

numerous standardized methods for evaluating

fl our in a food product (AACC 2000). Millers

must understand the product for which a particu-

lar fl our type will be used and evaluate wheat

choices based on tests that best represent that

product.

mm

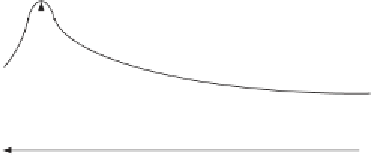

“W” Value = Area Under Curve

mm

L value

Fig. 19.4

The

P

value from an alveograph curve represents

the force required to blow a bubble from the dough, whereas

the

L

value is the extensibility of the dough before breaking.

The

W

value incorporates both

P

and

L

and is considered an

overall indicator of dough strength.

CANADIAN SYSTEM OF CLASSIFICATION

AND MARKETING

The Canadian Grain Commission (CGC) sets

Canadian wheat standards and classifi cations in

consultation with industry; however, the wheat

classifi cation approach in Canada is much more

restrictive than in the US. In particular, Western

Canada wheat cultivars must meet a visual

appearance standard referred to as kernel visual

distinguishability (KVD). The KVD standard

ensures that wheat classes are readily identifi able

throughout the handling system, and it has main-

tained kernel size and shape relatively uniform

within a class over time. Eastern Canada wheat

is not under the control of the Canadian Wheat

Board for marketing, so KVD is not required for

most eastern Canadian classes; Canada eastern

white winter is the exception. The KVD stan-

dard is well established and has demonstrated

benefi ts, but it has been criticized for limiting

cultivar development to meet niche markets and

for using visual criteria that are somewhat

subjective.

Two of the eight Western Canada classes con-

stitute the majority of Canada's wheat exports.

The largest class, often 15.0 million tonnes pro-

duced per year, is Canada western red spring

(CWRS). The second largest class, at nearly 5.0

million tonnes of production per year, is Canada

western amber durum. The remaining classes—

Canada western extra strong (CWES), Canada

western red winter (CWRW), Canada prairie

spring red (CPSR), Canada prairie spring white

(CPSW), and Canada western soft white spring

(CWSWS)—are considered minor because of

their small infl uence on export markets.

Through the CGC, Canada also takes a differ-

ent approach to grading wheat within a class,

fermentation time or an additive on dough per-

formance. Extensograph results also can be helpful

in understanding how dough will perform in

sheeted products such as pizza skins.

The alveograph is similar to the extensograph;

however, it measures dough by mimicking the gas

pressure created by yeast during fermentation.

The force required to infl ate and burst a bubble of

dough is graphed, and doughs with varying elastic

strengths may be compared (Fig. 19.4). Dough

that can be infl ated to a very large bubble without

breaking has high elasticity and is suitable for

yeast-levened bread products. Millers and bakers

use results of the alevograph test to ensure consis-

tency. The alveograph is especially well suited for

evaluating wheat with medium to weak dough

strength, such as that intended for use in cakes,

cookies, or other confectionery products.

Product performance

Although many chemical and functionality tests

are available to measure dough quality, fi nished

product performance is the only true measure

of the performance quality of wheat. Evaluating

wheat quality using a standardized fi nished

product methodology attempts to eliminate all

variables except those that exist within the wheat

and wheat fl our, and such an evaluation requires

a diversity of tests as varied as the fi nished prod-

ucts. Essentially, there are as many ways to evalu-

ate wheat as there are types of bread. Some groups

have attempted to create standardized bake tests

to establish a common language for and under-

standing of fi nished product quality. The Ameri-