Agriculture Reference

In-Depth Information

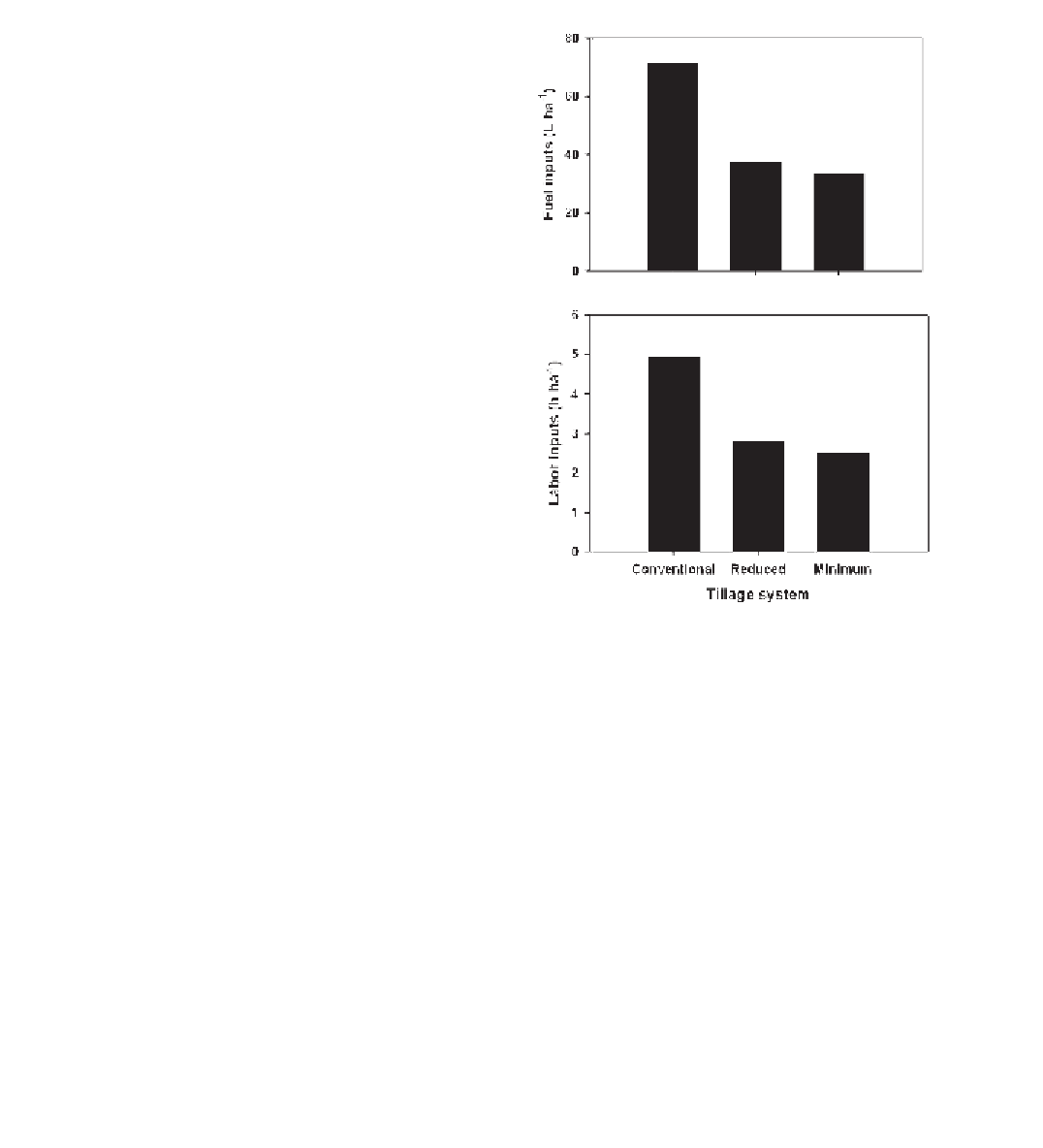

One of the reasons no-till acreage in wheat-

dominated production systems has increased over

the past 5 years is the decreased labor and fuel

requirements of no-till production systems. Pre-

vious research indicated that savings from reduced

machinery, labor, tractor fuel, and repair costs

associated with no-till production practices were

negated by increased herbicide costs (Epplin

et al., 1983). However, the price of glyphosate

(480 g of emulsifi able concentrate per liter) has

declined from a US average of $12 per liter in

1999 to $5 per liter in 2005, thus reducing by

more than one-half the cost of herbicidal control

of summer weeds from harvest in June until

planting in September. Coupled with that, record

oil prices have resulted in drastic increases in

farm diesel costs. The primary labor and fuel

savings for a no-till wheat production system is in

seedbed preparation, especially in more intensive

production systems such as those used in Europe

(Fig. 4.3). Many producers view no-till wheat

production as a way of trading high-priced, con-

ventional practices burdened with high environ-

mental impact (e.g., tractor-engine emissions,

fuel consumption, carbon loss, and erosion from

tillage operations) for low-priced, low-environ-

mental-impact production practices.

Advances in equipment technology have

also increased adoption of no-till practices.

Drift-reducing nozzles have allowed greater use

of glyphosate in areas adjacent to susceptible

crops (Derksen et al., 1999). Another area that has

seen great advancements in no-till wheat produc-

tion systems has been in no-till drill design and

performance. Proper seedbed preparation can

dictate the effi ciency of all subsequent operations

performed throughout the year. Wheat sown into

a poorly prepared seedbed or with poorly cali-

brated equipment has little chance of obtaining

optimal yield potential. Stockton et al. (1996)

found that actual fi eld emergence of wheat was as

low as 30% and averaged 57% of viable seed.

They indicated that the primary reason for poor

emergence was poor control of seeding depth,

causing most seed to be sown too deep. Many

conventional wheat drills at the time lacked

linkage between the disk openers and press

wheels.

Fig. 4.3

Fuel and labor inputs are reduced by almost

50% when conservation-tillage measures are introduced into

an intensive wheat production system. (Adapted from

Lithourgidis et al., 2006.)

Wheat drill design and performance has

improved dramatically since the work of Stockton

et al. (1996). Most conventional drills now have

the press wheel directly connected to the disk

opener as a standard design and seeding depth is

more precise and consistent. The fi rst no-till

drills were essentially heavy conventional drills or

conventional drills with a coulter-caddy attach-

ment. The results from these drills in heavy

residue such as maize stalks were often undesir-

able. Common problems included poor soil pen-

etration and inadequate seed-to-soil contact (see

Color Plate 8). Modern drills, however, can

deliver consistent and even seed distribution in a

wide range of seedbed conditions, from true no-

till to minimum till to conventional till.