Environmental Engineering Reference

In-Depth Information

30

Walnut shell

Corncob

Olive husk

Wheat straw

Sunflower shell

25

20

15

10

750

800

850

900 950 1000

Temperture, K

1050 1100 1150

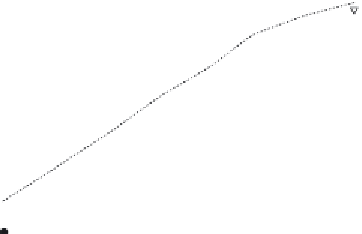

FIGURE 4.2

Plots for yields of hydrogen-rich gas from pyrolysis of agricultural residues versus tem-

perature in the presence of 30% Na

2

CO

3

.

Source

: Reproduced with permission from Demirbas [27].

for the utilization of bio-oil. Hydrogen production from renewable bio-oil is

an attractive idea for fuel, energy, and agricultural applications. In recent

years, hydrogen production via steam reforming of bio-oil has attracted more

and more attention. But because of the complicated composition of bio-oil

and carbon deposition on catalyst surface in the reaction process, currently,

studies have mainly focused on steam reforming of model compounds in

bio-oil and reforming catalysts [31]. The bio-oil can be stored and shipped

to a centralized facility where it is converted to hydrogen via catalytic steam

reforming and shift conversion [32]. Catalytic steam reforming of bio-oil at

1025-1125 K over a Ni-based catalyst is a two-step process that includes the

shift reaction [33]:

Bio-oil H O CO H

+

→ +

2

(4.4)

2

CO H O CO

+

→

+

H

2

.

(4.5)

2

2

The overall stoichiometry gives a maximum yield of 0.172 g H

2

·g

-1

bio-oil

(11.2% based on wood) [33].

CH O

+

1 26

.

H O CO

→

+

2 21

.

H

.

(4.6)

1 9

.

0 7

.

2

2

2

In reality, this yield will always be lower because both the steam reforming

and water-gas shift reactions are reversible, resulting in the presence of some

Search WWH ::

Custom Search