Environmental Engineering Reference

In-Depth Information

SORPTION-ENHANCED SMR REACTION

Gas Phase

CH

4

+ H

2

O

CH

4

+ H

2

O = CO + 3H

2

CO + H

2

O = CO

2

+ H

2

Fuel Cell Grade

Hydrogen

Admixture of CO

2

Chemisorbent + SMR Catalyst

THERMAL SWING REGENERATION

Gas Phase

CO

2

Super Heated

Steam

H

2

O + CO

2

Admixture of CO

2

Chemisorbent + SMR Catalyst

Heat

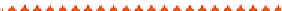

Basic Principles of TSSER - SMR Concept

FIGURE 2.1

Schematic of the thermal swing sorption-enhanced reaction (TSSER)-steam-methane

reforming (SMR) concept.

Source

: Reproduced with permission of Beaver et al. [2].

In a recent study, a new concept based on sorption-enhanced reaction

(SER) for steam-methane reforming (SMR) was demonstrated to directly

produce fuel-cell grade H

2

(∼10 ppm CO) with very high CH

4

to H

2

conver-

sion efficiency (>99%) using an admixture of a commercial SMR catalyst

and a CO

2

chemisorbent, K

2

CO

3

promoted hydrotalcite [2]. The reaction was

carried out at a much lower temperature (520-590°C) than the conventional

reaction temperature of 700-900°C without sacrificing the reactor perfor-

mance. It also eliminates the subsequent H

2

purification step by a conven-

tional PSA process. Figure 2.1 shows a schematic of the thermal swing

sorption-enhanced reaction (TSSER)-steaming methane reforming (SMR)

concept. The overall outcomes are attributed to four related factors: (a) favor-

able thermodynamic equilibrium of the highly endothermic SMR reaction at

the higher reaction temperature, (b) faster kinetics of SMR reaction at higher

temperatures, (c) favorable removal of CO

2

from the reaction zone at lower

temperatures, and (d) higher cyclic working capacity for CO

2

chemisorption

at higher temperature.

Search WWH ::

Custom Search