Environmental Engineering Reference

In-Depth Information

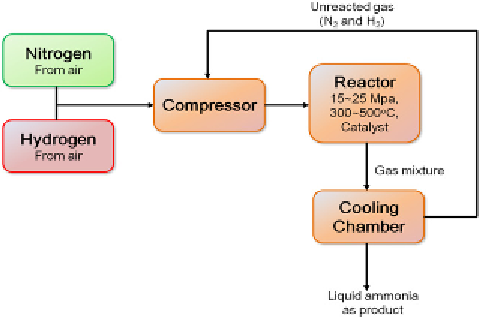

FIGURE 10.6

A flow chart illustration of the main components in a typical Haber process [11].

pollutants such as sulfur and nitrogen from chemical fuels. During this

process, hydrogen gas will be used to hydrogenate sulfur and nitrogen com-

pounds, and finally remove them in the form of H

2

S and NH

3

gases [9].

10.3 HYDROGEN UTILIZATION IN CHEMICAL INDUSTRY

10.3.1 Ammonia Production: The Haber Process

The Haber process, also known as Haber-Bosch process, is the well-

established method for production of ammonia using nitrogen and hydrogen

as precursor gases. It was first reported by two German scientists Fritz Haber

and Carl Bosch in the early twentieth century. This process has been refined

and optimized for industrial-level production of ammonia and other nitrogen

fertilizers. This is one of the most important processes in chemical industry,

and significantly, it consumes almost 50% of the total global hydrogen pro-

duction [9].

Figure 10.6 shows a schematic illustration of the Haber process. The

Haber process takes nitrogen gas from air and combines it with hydrogen

from natural gas to form ammonia:

Catalyst

MPa

→

−

1

N

+

3

H

2

NH

; ∆

H

=−

9

2 22

.

kJ mol

⋅

.

←

(10.1)

2

2

3

15 25

−

,

300 500

~

°

C

Reaction pressure and temperature are typically set to be 15∼25 MPa and

300∼500°C. An optimal conversion efficiency of ∼15% can be achieved in

this single-step reaction. Unreacted gases will be separated from liquid

Search WWH ::

Custom Search