Environmental Engineering Reference

In-Depth Information

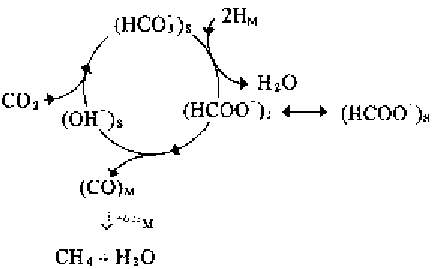

FIGURE 6.16

Schematic illustration of the CO

2

methanation process via hydrogenation. S stands for

the support, M for the metal, and I for the metal-support interface.

Source

: Adapted from Marwood

et al. [50].

For direct methanol generation from CO

2

hydrogenation, the reaction is

given as:

CO

+

3

H

→

CH OH H O H

+

∆

=−

49 5

.

kJ mol

⋅

−

1

.

(6.19)

2

2

3

2

298

K

Based on thermodynamics, a decrease in temperature and an increase in

pressure would favor methanol formation. By-products for methanol synthe-

sis include CO, hydrocarbons, and higher alcohols. Thus, a highly selective

catalyst is needed to avoid the formation of undesired by-products for metha-

nol synthesis. Among the many metal-based catalysts, Cu remains the

primary active catalyst component, together with various modifiers, such as

Zn, Zr, Al, Ce, Si, Ti, B, and Cr. The catalysts are usually dispersed on oxide

supports, such as ZnO and ZrO

2

, which can play an important role in the

reaction by affecting the formation and stability of the catalysts, as well as

interaction between catalysts and promoters. Methanol selectivity is strongly

dependent on the specific catalysts and supports used, and in some cases,

near 100% selectivity is reached [55]. Despite extensive studies, the reaction

mechanism of methanol synthesis is still not well understood. One model

suggests that the reaction is occurring at the interfaces of Cu and oxides with

CO

2

adsorbed on the oxides and H

2

dissociating on Cu [56].

6.5 SUMMARY

Metal hydrides represent one of the most promising materials for hydrogen

storage. They usually have very high volumetric density but low gravimetric