Environmental Engineering Reference

In-Depth Information

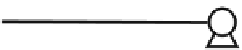

N

2

Flow breaker

0.2 µm filter

Peristaltic pump

Flat plate reactor

Flow

breaker

Recycle

Growth

medium

Effluent

Peristaltic pump

Fig. 1.3

Schematic illustration (not to scale) of a flat plate reactor used to image biofilms and

study uranium immobilization and local chemistry in biofilms

3. Drain the reactor, and then fill it with sterile deionized (DI) water. Reverse the

recycle line and drain it again. Repeat the fill and draw procedure at least 5 times.

4. Drain the reactor again and fill it with growth medium. Repeat the fill and draw

procedure for growth medium at least three times.

5. Inoculate the reactor aseptically with 30 mL of inoculum through slow manual

injection using a syringe.

6. Stop the recycle line and wait for 30 min to allow the initial attachment of the

bacteria. Then start the recycle at a very slow rate and increase gradually up to

the operating recycle flow rate within a few minutes.

7. Operate the reactor overnight in batch mode to allow the bacteria to grow.

8. Start the nutrient pumps and deliver the nutrient solution at the operating

conditions to grow the biofilm.

9. Uranium can be added the medium after biofilm establishment. The growth

medium should not react with uranium. Otherwise it is difficult to identify the

microbiological factors involved in uranium immobilization.

1.3.4.2 Fixed Bed Column Reactor

FBCRs are usually used to simulate subsurface biofilms growing on various surfaces

to investigate biofilm-mineral interactions. These reactors are usually operated for

several months and then disassembled for various measurements of the biofilms

grown on the mineral surfaces.

A FBCR typical of those used in our studies is shown in Fig. 1.4A. It is made of a

clear polycarbonate tube with an internal diameter of 2.5 cm and a length of 40 cm.

A typical column is filled with selected minerals and then sealed. To ensure the uni-

form delivery of growth medium, flow distributors made of glass beads (0.5 cm in

diameter) are entrapped between two plastic sieves and these are placed in the inlet