Environmental Engineering Reference

In-Depth Information

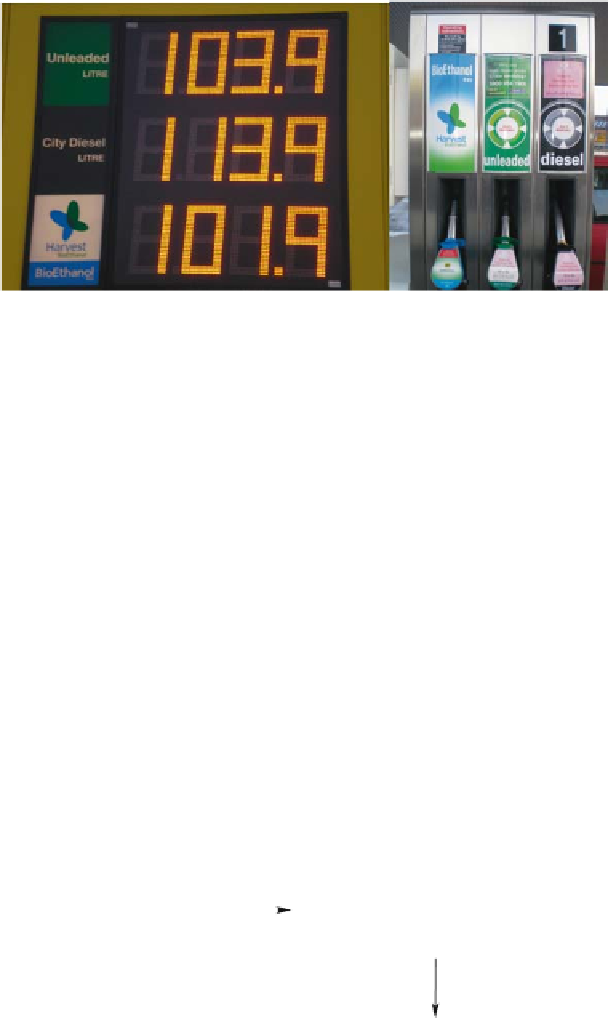

Fig. 8.5

E85 bioethanol blend can be found at cost-competitive prices in many petrol stations all

over the UK (May 2008)

The common feedstocks employed for the production of first generation

bioethanol are energy crops including sugar cane, corn, wheat, maize and sugar beet

(“food” crops) although a great potential of grain or sweet sorghums in replacing

maize and sugar cane, respectively, has been reported [50].

First generation bioethanol is generally obtained by biological conversion involv-

ing two key steps: hydrolysis and fermentation, followed by a distillation and

dehydration of the bioethanol produced to obtain a higher concentration of alcohol

to make it suitable for its use as automotive fuel.

Hydrolysis (saccharification)

. The digestion of the feedstock is normally per-

formed via enzymatic hydrolysis using mixtures of amylases enzymes to convert the

starch into sugars. Sugar cane and beet directly produce sugars that can be directly

fed into the bioreactor.

Fermentation

. The released sugars are subsequently fermentated to ethanol using

yeast (e.g.

Saccharomyces cerevisiae

) using a similar process to that used in beer

and wine-making [51, 52]. The invertase enzymes present in the yeast catalyse the

conversion of sucrose into glucose and fructose that are subsequent transformed into

ethanol and carbon dioxide by the zymases enzymes (Fig. 8.6).

Invertase

+

+

C

6

H

12

O

6

C

6

H

12

O

6

C

12

H

22

O

11

H

2

O

Fructose

Glucose

Sucrose

Zymase

+

2C

2

H

5

OH

2CO

2

Ethanol

Fig. 8.6

Production of bioethanol via fermentation of hydrolysed sugars from energy crops