Environmental Engineering Reference

In-Depth Information

states were starting operations, or were under construction/planning. Relatively

large plants can be found in Lithuania, Poland and Romania, with capacities of

100,000 tonnes/year. The conventional methodology for the production of biodiesel

involves the transesterification of triglycerides (TG) from vegetable oils (palm, corn,

soybean, rapeseed, sunflower, etc.) with short chain alcohols including methanol

and ethanol to yield fatty acid (m)ethyl esters (FAM/EE) and glycerol as by product

(Figs. 8.3 and 8.4).

Several reviews on the preparation of biodiesel from different feedstocks can be

found in the literature [12-15]. A very good overview of such technologies has been

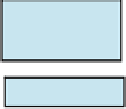

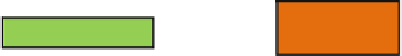

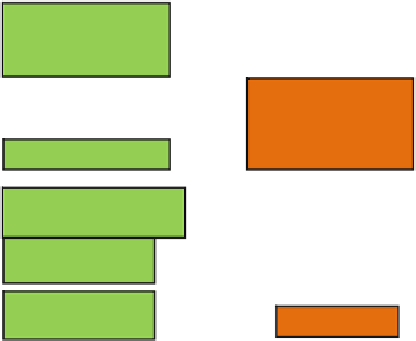

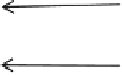

TECHNOLOGIES

BIOFUELS

FEEDSTOCKS

Microbial (in)direct

photolysis/

Fermentation

Biohydrogen

Generic Biomass

Non edible

feedstocks (e.g

non-food crops,

microbial oil)

Transesterification/

Hydrogenation

Biodiesel

2

nd

Generation

biofuels

Anaerobic digestion

Biogas

Synthetic

fuels

Waste oils/fats

Gasification/ pyrolysis/

catalytic cracking

Wood, agricultural

and marine waste

Gasification/

Fermentation

Bioalcohols

Saccharification/

Fermentation

Sugar crops

Biobutanol

Oil crops

Biodiesel

and others

Transesterification

1

st

Generation

biofuels

Sugar and

starch crops

Fermentation

Bioethanol

Fig. 8.3

The biofuels ladder. Road map of biofuels production from feedstocks and technologies

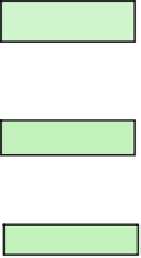

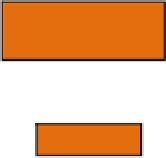

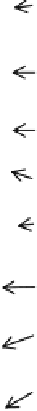

O

O

R

O

OH

O

R

Y

O

+

O

3HY

+

OH

R´

O

T

=

50-70

o

C

Y

O

(Y = OMe,

OEt, OBut)

R"

OH

(Cat = NaOMe,

NaOEt, NaOH)

O

Y

R´

R"

Generic Triglyceride

Fatty acid methyl esters

Glycerol

(R,R',R" = C13-C23)

Fig. 8.4

Conventional transesterification of TG for the production of biodiesel