Environmental Engineering Reference

In-Depth Information

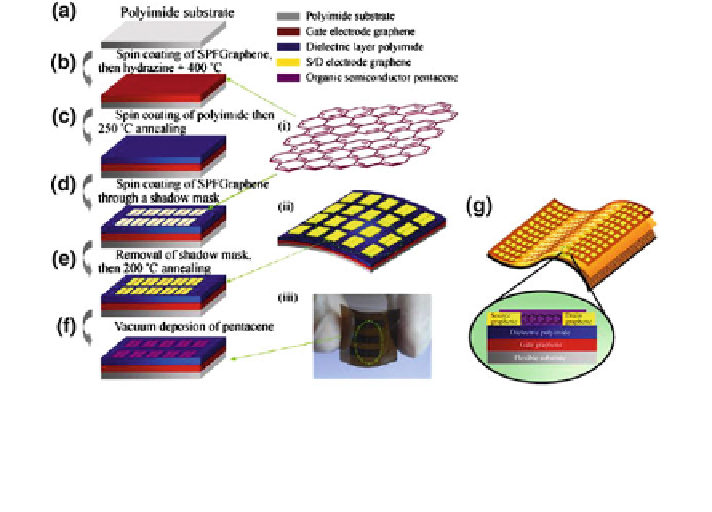

Fig. 4.8 (a-f) Schematic illustration of the fabrication of pentacene OFET devices. (i) Structure

of graphene; (ii) a schematic representation of the unfinished OFET before adding the pentacene

layer, showing its good flexibility; (iii) the finished pentacene OFET on a flexible PI substrate

when bent under force. (g) A schematic illustration of the structure of flexible bottom-contact

OFETs based on a pentacene film. Reproduced with permission [

54

]. Copyright 2011, Springer

is generally Al. Recently, Lee et al. reported a semitransparent inverted-type

polymer solar cell using a top laminated graphene electrode [

55

]. The device was

fabricated with a standard inverted structure using ZnO as electron transport layer,

replacing the PEDOT:PSS hole-transporting layer by GO and the top metal

electrode by the laminated CVD graphene film (Fig.

4.9

a). The detailed fabrica-

tion process was presented in Fig.

4.9

b. The resulting device structure was ITO/

ZnO/P3HT:PCBM/GO/graphene. As illuminated from the ITO side, the semi-

transparent device achieves a best PCE of 2.50 % when the top electrode with 10

layers of graphene was employed, corresponding to 76 % of that of the standard

opaque cell. The detailed performances were summarized in Table

4.3

. Similar

work has also been reported by Cox et al. using CVD graphene as back electrode

for small molecule OPV device [

56

]. These results indicate that besides employed

as window electrode in OPV, it can be used as back electrode. So, flexible, all-

carbon solar cells can be constructed using graphene as both anode and cathode.

4.4.3 All-Carbon Conductive Circuit

From solution-processing graphene films, we fabricated various graphene-based

microcosmic patterns and structures by computer controlled laser cutting

(Fig.

4.10

a-d, steps i-v) [

57

]. Furthermore, a complete working prototype of a

flexible

WORM

memory

card

coupled

with

a

real

data

retrieving

system

Search WWH ::

Custom Search