Environmental Engineering Reference

In-Depth Information

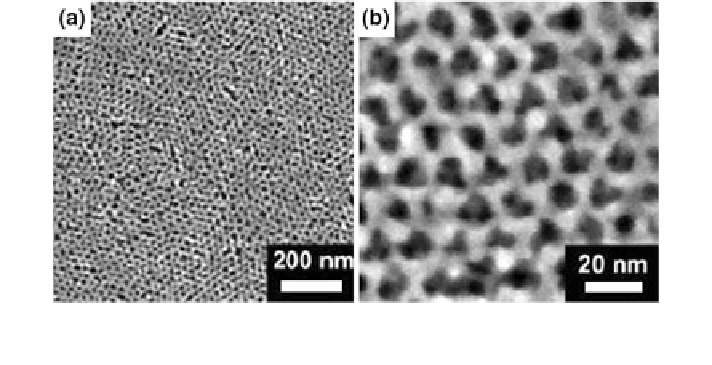

Fig. 9.5 SEM images of the self-assembled porous TiO

2

film, a lower magnification, b higher

magnification. Reproduced with permission from Ref. [

16

]

other efforts have also been done to prepare HSCs based on porous TiO

2

film

[

18

,

58

-

60

]; however, the PCEs are typically lower than 0.5 % except for the cases

when interface modifications are applied [

61

,

62

]. However, it is difficult to optimize

the polymer/TiO

2

interface and the complete infiltration of polymers into TiO

2

net-

work is also a challenge [

63

]. These problems could be overcome by simultaneous

deposition of the blend of polymer and TiO

2

particles and a 0.42 % PCE has been

achieved under AM 1 irradiation by Kwong et al. [

20

,

21

], but there are also some

disadvantages that could limit further improvement of the device performance,

namely, for the different nature of the two distinct components which cannot be simply

dissolved in the same solvent. Direct blending will cause unavoidable aggregation of

TiO

2

particles resulting in poor organic-inorganic interface, and therefore low effi-

ciency [

34

]. Capping TiO

2

nanocrystals with amphiphilic molecules, e.g., oleic acid or

trioctylphosphine oxide could improve their solubility in organic solvents, but the long

alkyl chain of these molecules might hinder the charge transfer process, sometimes

ligand exchange is needed for better charge transfer, all of this will complicate the

fabrication of such devices and it is still difficult to control the morphology and

dispersion of TiO

2

particles in polymer matrix [

64

,

65

].

The aforementioned problem could be avoided by using Ti precursor instead of

TiO

2

particles; unfortunately, a new problem arose, i.e., the low crystallinity of

TiO

2

due to the absence of high temperature sintering, which could also lead to

poor device performance [

19

].

All these drawbacks might be overcome by using ZnO nanocrystals, since

soluble ZnO nanoparticles could be synthesized without using any surfactant.

Uniform ZnO/conjugated polymer composite films have been easily prepared [

34

]

and ZnO-MDMO:PPV-based devices gave PCEs of about 1.6 % [

23

,

25

,

66

] while

the ZnO:P3HT gave 0.9 % [

26

] under AM 1.5, 1 sun condition. Both devices show

much higher efficiencies than that of TiO

2

: polymer-based devices owing to the

improved polymer/nanocrystal interface. Besides, crystallized ZnO nanoparticles

could be prepared under low temperature by using a highly reactive ZnO precursor

Search WWH ::

Custom Search