Environmental Engineering Reference

In-Depth Information

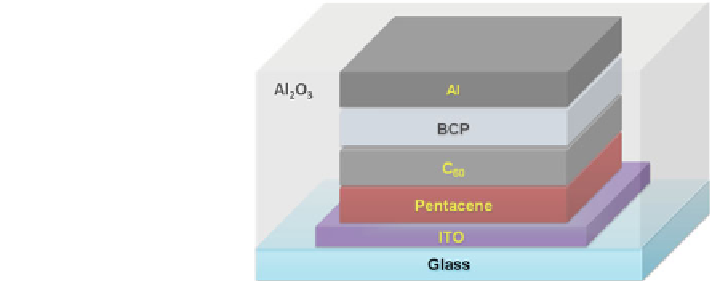

Fig. 6.20 Schematic of

device structure [

107

]

The device encapsulated with only UV epoxy degrades by a slower rate, whose

performance decreases to 50 % of the initial value after 100 h and to 25 % after

almost 250 h upon exposure to ambient atmosphere due to a short-term protection

of epoxy. The devices with Al

2

O

3

by ALD and with or without UV epoxy layer

have PCE and J

sc

within 6 % of their initial values after 6,145 h of exposure to

ambient atmosphere.

Moreover, Sarkar et al. did not use the UV-curable epoxy and developed

improved ultrathin Al

2

O

3

layers, grown by using ALD, as primary barrier layers

for encapsulation of OPV devices [

105

], as shown in Fig.

6.22

. The encapsulation

characteristics of this barrier layer can be improved by replacing H

2

O with O

3

as

the ALD oxidant, exhibiting superior device encapsulation to the barrier layer

grown by using H

2

O. This Al

2

O

3

barrier layer was done without any additional

UV-curable epoxy resin film as a sealant for protecting the devices from ambient

moisture and oxygen. Through optimization, the optimal thickness of Al

2

O

3

is

18 nm to function well, and thus 210 cycles of O

3

-Al

2

O

3

give the best device

encapsulation exhibiting 80 % of its initial efficiency over a period of 500 h. The

authors have compared two different ALD temperatures functioning as an

annealing step beneficial to the formation of phase separation in the active layer.

Additionally, Luo et al. presented a thin layer of MnO inserted in between

photoactive layer and metal cathode to improve the device efficiency and air

stability [

109

]. The results indicate that MnO can serve as electron-transporting

layer and protection layer from damages caused by moisture and oxygen. The

OPV device with 3 nm MnO layer retains a PCE of 28.42 % of its initial value

after 2 weeks while the device without MnO layer has only 6.03 % of initial PCE

just after 2 days without encapsulation. It is promising to use such a MnO layer to

enhance both device efficiency and operation stability.

The most common technique to obtain an ultra-high barrier layer is to use

alternating organic-inorganic multilayer, i.e., inserting inorganic barriers between

polymer buffers to reduce the number of pinholes [

110

], resulting in smoothly

coated surface, decreased mechanical damage, and increased thermal stability

[

18

]. On the other hand, stacked structure is produced by repeating the alternating

process, allowing organic layers to ''decouple'' the defects from neighboring

inorganic layers. Madakasira et al. reported the conformal deposition of parylene

Search WWH ::

Custom Search