Environmental Engineering Reference

In-Depth Information

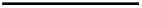

Biogas

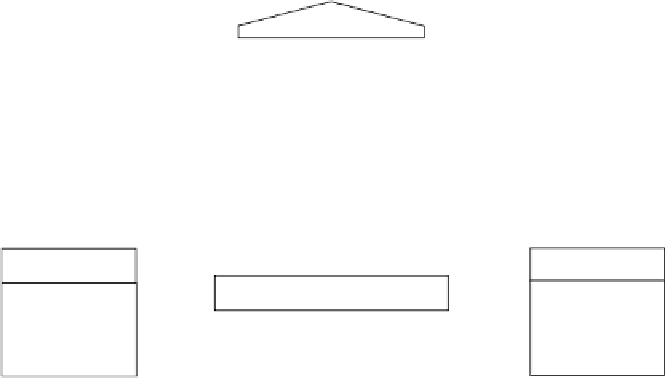

Digester

T = 55-60°C

T = 55°C

CHP

Standard

70/90°C

cycle

Preparation

buffer tank

Storage-post-

treatment tank

T = 30-45°C

Q

R

T = 30-35°C

T = 10-20°C

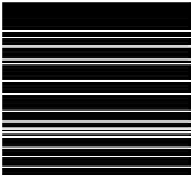

FIGure 32.11

Heat regeneration.

more stable digested substrate, smaller digesters, pathogen removal, etc. There are substrates that

require extensive pretreatment; especially this is the case for lignocellulosic material (like spent

brewery grains) that require energy intensive pretreatment to be successfully digested at all. In such

cases, the energy loss for pretreatment must be accounted for in the energy production. In many

cases it cannot outweigh the economy of the process; it may well happen that the parasitic energy

demand is too high.

32.4

WasteWater treatment

32.4.1 a

griculturE

w

aStEwatEr

t

rEatmEnt

The different types of contamination of wastewater require a variety of strategies to remove the

contamination.

32.4.1.1 solids removal

Most solids can be removed using simple sedimentation techniques with the solids recovered as

slurry or sludge. Very fine solids and solids with densities close to the density of water pose special

problems. In such case, filtration or ultrafiltration may be required. Alternatively, flocculation may

be used using alum salts or the addition of polyelectrolytes

32.4.1.2 removal of Biodegradable organics

Biodegradable organic material of plant or animal origin is usually possible to treat using extended

conventional wastewater treatment processes such as activated sludge or trickling filter.

Activated sludge is a biochemical process for treating sewage and industrial wastewater that uses

air (or oxygen) and microorganisms to biologically oxidize organic pollutants, producing a waste

sludge (or flock) containing the oxidized material. In general, an activated sludge process includes:

• An aeration tank where air (or oxygen) is injected and thoroughly mixed into the wastewater.

• A settling tank (usually referred to as a “clariier” or “settler”) to allow the waste sludge

to settle. Part of the waste sludge is recycled to the aeration tank and the remaining waste

sludge is removed for further treatment and ultimate disposal.