Environmental Engineering Reference

In-Depth Information

to get a constant biogas flow. Most modern biogas plants are equipped with co-generation units,

also called combined heat and power units (CHP), which require constant gas flow for steady and

efficient operation. There are several possibilities of biogas storage: they can roughly be divided into

low-pressure (10-50 mbar) and high-pressure storage (over 5 bar). Low-pressure storage is used in

on-site installations and for gas grid delivery; high pressure storage is used for long tem storage, for

distant transport in high pressure tanks, and in installations with scarce space for volume extensive

low pressure holders.

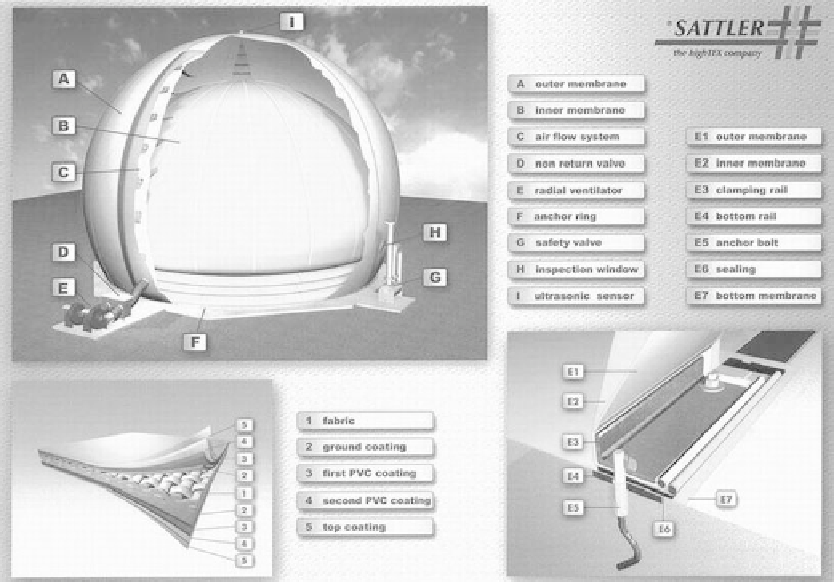

Low pressure biogas holders come in many variations. It is possible to include a biogas holder

in the design of the digester. The most known is the digester with a movable cover. These digesters

are less common because a movable cover requires increased investment and operating expenditure.

More common are external biogas holders that are widely commercially available. An example of a

modern biogas holder is presented in Figure 32.9.

Low pressure biogas holders require an extensive volume of 30 to 2000 m

3

(Deublin and

Steinhauser 2008). Usually, the pressure is kept constant and the volume of the bag is varied. High

pressure biogas holders are made of steel, are of constant volume, and are subject to special safety

requirements. They do require more complex equipment for compression and expansion of the gas

and are harder and more cost effective to operate and maintain.

Biogas is not pure methane and carbon dioxide, but contains many components such as water

droplets, dust, substrate microparticles and trace gases. Therefore, biogas treatment is necessary

to preserve equipment. Solid particles can be filtered out, and sludge and foam are separated in

cyclones. For removal of trace gases, where hydrogen sulfide (H

2

S) is the most disturbing because

of its corrosive properties, processes like scrubbing, adsorption, and absorption are used. In some

cases, drying is also required (usually to the relative humidity of less than 80%).

FIGure 32.9 (see color insert)

An example of a commercially available biogas holder. (From Sattler,

Biogas storage systems, 2009. http://www.sattler-ag.com/sattler-web/en/products/190.htm)