Environmental Engineering Reference

In-Depth Information

biodegradability; a mesophilic process can rarely achieve higher loads than 5.0 kg m

-3

/day and

thermophilic 8.0 kg m

−3

/day, respectively. Locally in the digester for a short period of time, higher

loads can be achieved; however, it is not advisable to run continuously on such high loads.

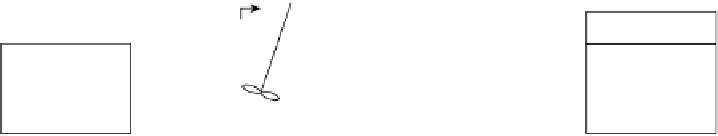

To achieve better efficiency and higher loads stage separated process can be applied (Figure 32.7).

In this case, the whole substrate or just portions of the substrate that are not easily degradable

are treated first in hydrolysis-acidogenic stage reactor and after that in the methanogenic reactor.

By separating the biological processes in two separate tanks, each can be optimized to achieve

higher efficiency as if in just one tank, where all biological processes are occurring simultaneously.

Much research has been published giving considerable attention to this kind of process (Dinsdale

et al. 2000; Song et al. 2004; De Gioannis et al. 2008; Ponsá et al. 2008). Both stages can be

either mesophilic or thermophilic; however, it is preferred that the hydrolysis-acidogenic reactor is

thermophilic; and methanogenic is mesophilic. Typical HRT for hydrolysis-acidogenic reactor is 1-4

days (thermophilic), depending on the substrate biodegradability. Typical HRT for the methanogenic

reactor is 10 to 15 days (mesophilic) and 10-12 days (thermophilic). Advantages of this process

beside shorter HRT are higher overall volume loads (20% or more). Many authors also reported

slightly better biogas yields (Messenger et al. 1993; Han et al. 1997; Roberts et al. 1999; Tapana

and Krishna 2004). The only disadvantage is that this process requires more sophisticated process

control and equipment, but the construction is more cost effective.

32.3.3.5 Flow-through Processes

Flow-through processes, such as the UASB process (Figure 32.8), are used only for substrates where

organic material is in dissolved form with solids content at maximum 1-5 g/L. In this substrate

category are mostly wastewaters of industrial origin (beverage industry). A detailed depiction of the

process is presented therefore in the wastewater treatment section.

32.3.3.6 Posttreatment and substrate use

After the substrate has been digested, it needs additional treatment. There are several possibilities of

digested substrate use. The most common and most used possibility in farm waste treatment is using

the digested substrate as a fertilizer. It can be used wet or dewatered. Wet substrate (total solids

concentration 1-5% by mass) is taken from the post-treatment tank and used. However, it must be

considered that fertilizing is possible only twice (sometimes once) annually. The post-treatment

container, therefore, must be designed accordingly. A possible solution is a lagoon, where digested

substrate is stored and additionally stabilized and mineralized during the storing time. When using

Biogas

Preparation

buffer tank

Storage-post

treatment tank

Biogas

Hydrolysis-

acidogenic stage

digester

Methanogenic stage

digester

Possible recirculation

FIGure 32.7

Two-stage anaerobic digestion.