Environmental Engineering Reference

In-Depth Information

Biogas

Biogas

Effluent

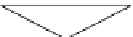

1

st

phase-load

2

nd

phase-digestion

3

rd

phase-settling

4

th

phase-unload

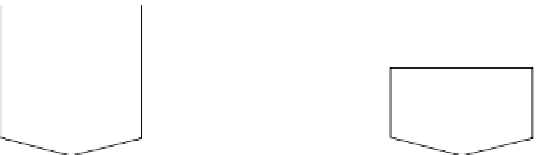

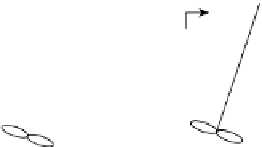

FIGure 32.4

Batch ASBR process schematic.

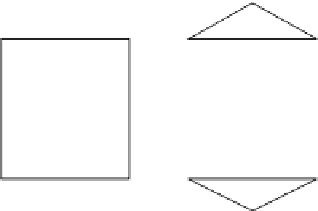

Process cycle

Reactor 1

New batch

phase 1

Self-recirculation

phase 2

Old batch

phase 3

Self-recirculation

phase 4

Coupling

Coupling

Load

Unload

Old batch

phase 3

Reactor 2

Self-recirculation

phase 4

New batch

phase 1

Self-recirculation

phase 2

Unload

Load

Coupling old-new batch

Self-recirculation

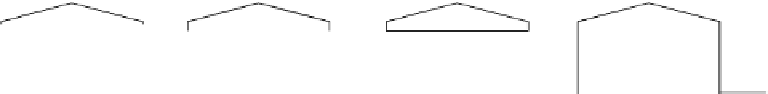

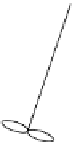

FIGure 32.5

Batch solid anaerobic digestion scheme.

once and degrades without any interference until the end of the cycle phase. This leads to temporal

variation in microbial community and biogas production. Therefore, batch processes require more

precise measurement and monitoring equipment to function optimally. Usually, these reactors are

at least built in pairs, sometimes even in higher numbers. This achieves a more steady flow of

biogas for instant use. The tank is usually emptied between the cycles to a certain exchange volume,

which in case of anaerobic digestion is rarely more than 50% of total reactor volume. The residue

in the tank is microbial inoculum for the next cycle. This makes batch reactors more voluminous

than conventional continuous reactors; however, they do not require equalization tanks and the

total reactor volume is usually less than in conventional processes. They can be coupled directly

to the waste discharge; however this limits the use to more industrial processes (for example food

industry) and less to farm waste production. The typical cycle time is 1 week.