Environmental Engineering Reference

In-Depth Information

Dekker and Wallis (1983) reported steam hydrolysis of sunflower seed hulls at 200°C for 5 min

followed by explosive defibration that solubilized more than 80% of the total hemicellulose and 85%

of the pectic substances. The remaining residue, which consisted of cellulose (38%), lignin (45%),

and residual hemicellulose (7%), was highly susceptible to hydrolysis by cellulases. Vaithanomsat

et al. (2009) also performed pretreatment of acid-soaked sunflower stalks by steam explosion at

207°C and 21 kg/cm

2

for 3 min to fractionate the cellulose, hemicellulose, and lignin. Ruiz et al.

(2006) used 220°C for 5 min as the pretreatment conditions for sunflower stalks. In our laboratory,

we used a low pressure of 1.05 kg/cm

2

for 30-90 min in an autoclave for NaOH -soaked sunflower

stalks and hulls (Sharma 2000; Sharma et al. 2002b). Similarly, Okur and Saracoglu (2006) used

relatively mild conditions of 0.7 M acid and 90°C for pretreatment of sunflower hulls.

Acid and alkali hydrolysis have been used for pretreatment of sunflower hulls and stalks. Whereas

Jimnez and Bonilla (1993), Vaithanomsat et al. (2009), and Okur and Saracoglu (2006) used acids,

Soto et al. (1994) treated the ground sunflower hulls with NaOH (0.5 to 3% w/w) in an autoclave at

120°C for 0.5, 1, and 1.5 h. They reported that the higher the NaOH concentration, the greater the

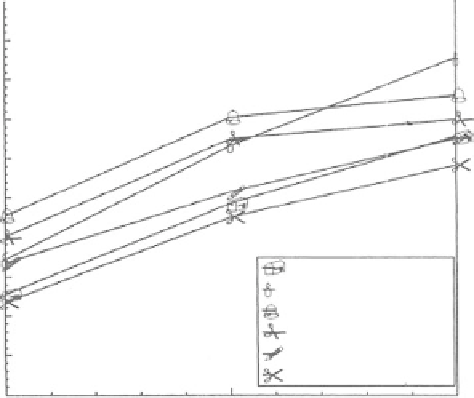

delignification. We also used alkali (0.25-1.5% NaOH; Figure 30.1) and standardized 0.5% NaOH

for pretreatment of sunflower stalks and hulls (Sharma et al. 2002b, 2004) that revealed 51 and 53%

cellulose, 17 and 17.5% hemicellulose, and 14.6 and 11.40% of lignin in sunflower stalks and hulls,

respectively (Sharma 2000; Sharma et al. 2002a). The extraction yield (fraction of sunflower stalks

recovered after pretreatment) was 66% (Sharma et al. 2002a).

30.5 cellulase ProductIon

Even a cursory perusal of current scientific literature shows cellulose hydrolysis by cellulases to be

among the most intensively studied topics. Each and every aspect of cellulase production such as

isolation and mutation of cellulolytic microorganisms, mode of fermentation, process optimization,

genetics and regulation at a molecular level, mode of action, process economics, and cellulase

recycling have been investigated comprehensively. Several workers have reviewed the cellulase

production and technology aspects (Saddler et al. 1986; Srinivasan and Seetalaxman 1988; Beguin

1990; Wyman 1994; Bothast and Saha 1997; Ward 2002; Juhasz et al. 2004; Immanuel et al. 2006;

Kocher et al. 2008).

200

190

180

170

160

150

140

0.25% (w/v) NaOH

130

0.50% (w/v) NaOH

0.75% (w/v) NaOH

120

1.00% (w/v) NaOH

1.25% (w/v) NaOH

1.50% (w/v) NaOH

110

100

0.5

1

1.5

Autoclaving time (hrs) at 1.05 kg/cm

2

FIGure 30.1

Effect of NaOH and autoclaving at 1.05 kg/cm

3

on the enzymatic hydrolysis of sunflower

stalks. Incubation time 48 h.