Environmental Engineering Reference

In-Depth Information

6

4

3

5

9

8

10

11

7

1

2

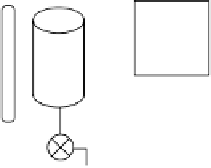

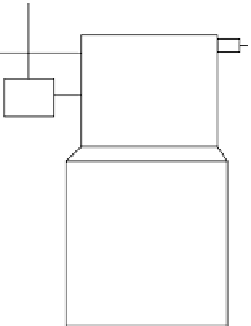

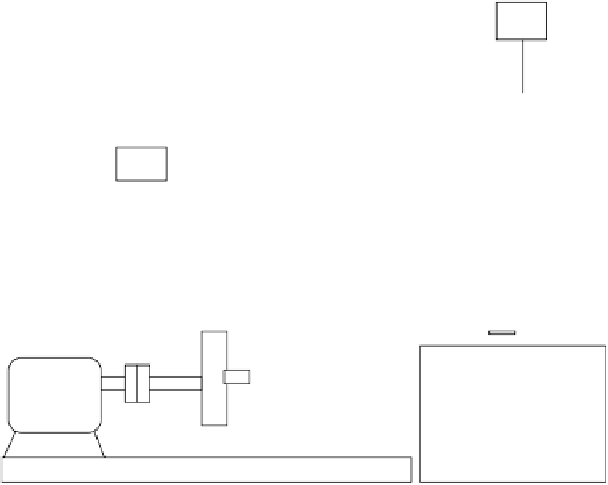

2. Dynamometer

1. Test engine

3. Biodiesel tank

4. Burette

5. Fuel filter

6. Air surge tank

7. TDC pickup

8. Pressure transducer

9. Charge amplifier

10. Analog to digital

converter card

11. Computer

FIGure 25.4

Experimental setup.

taBle 25.4

Properties of different Biodiesel Fuels

Iodine value

(g iodine/100

g oil sample)

heating value

(mJ/kg)

density (kg/m

3

)

cetane number

ROME

885

39.5

47.8

160

LOME

882

39.3

51.0

140

KOME

878

39.5

52.0

95

NOME

876

39.8

58.7

83

MOME

875

40.5

61.4

65

ROME, rubberseed oil methyl ester; LOME, linseed oil methyl ester; KOME, karanja oil methyl ester;

NOME, neem oil methyl ester; MOME, mahua oil methyl ester.

25.4.1.1 density

The density of a fuel shows how close the molecules are packed in the structure. A higher-density

fuel has a more closely packed structure than a lower-density fuel. Fuel density is commonly

expressed in kilograms per cubic meter. The greater the fuel density, the greater the mass of fuel that

can be stored in a given tank and the greater the mass of fuel than can be pumped for a given pump.

The density of a fuel affects dynamic injection timing, ignition delay, and thereby NOx emis-

sions. However, these properties are uncertatin indications of fuel quality unless correlated with