Environmental Engineering Reference

In-Depth Information

for sodium hydroxide (NaOH) (Fanguri and Hanna 1999). To complete a transesterification

stoichiometrically, a 3:1 molar ratio of alcohol to triglycerides is needed. The reaction can be

catalyzed by alkalis, acids, or enzymes. The alkali include NaOH, potassium hydroxide (KOH),

carbonates, and the corresponding sodium methoxide, sodium ethoxide, sodium peroxide, and

sodium butoxide Sulfuric acid, sulfonic acids, and hydrochloric acid are usually used as acid

catalysis. Lipase can be used as biocatalysts. Alkali-catalyzed transesterification is much faster

than acid-catalyzed transesterification and is most often used commercially (Nelson et al. 1996)

.

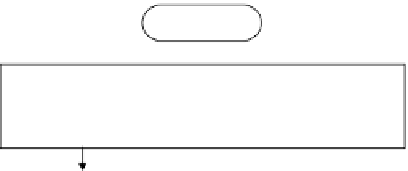

According to the quality of the parent oil, the selection of a transesterification process can be made

as shown in Figure 25.1 and it can be explained as follows:

• If the free fatty acid (FFA) content and moisture content of parent vegetable oils are less

than 0.5%, a single-stage transesterification process can be chosen.

• When the FFA content is less than 0.5% but the moisture content is greater than 0.5%, the

moisture content can be removed by heating the oil at 110°C for approximately 1 h with

stirring. Then, the biodiesel can be produced from single-stage transesterification.

Start

1. Determination of

• Free fatty acids (FFA) content and

•Moisture content of raw vegetable oils

2. FFA < 0.5%,

moisture

content < 0.5%

3. FFA < 0.5 %,

moisture

content > 0.5 %

No

Yes

Yes

3a. Heating of oil @

100°C with stirring

for one hour and

removal of moisture

No

5. Single-stage

transesterification

4. FFA > 0.5 %,

moisture

content < 0.5 %

Yes

4a. Two-stage

transesterification

No

4b. Three-stage

transesterification

Stop

FIGure 25.1

Flow chart for the selection of transesterification process.