Environmental Engineering Reference

In-Depth Information

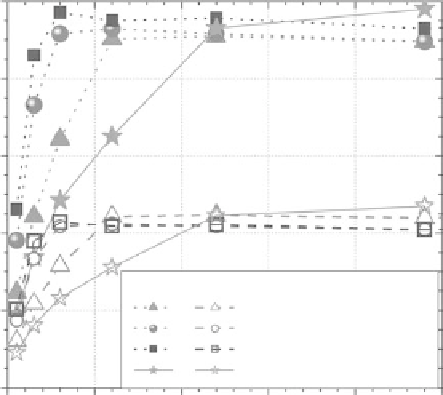

feedstock species. For example, bisulfite of about 8% is required for softwood, whereas only 2-4% is

required for hardwood. Cellulose-to-glucose conversion over 90% can be easily achieved even for soft-

wood with low enzyme loading. The pretreatment is directly applied to wood chips without further size

reduction. Furthermore, size-reduction energy consumption after pretreatment was only 20-50 Wh/kg

oven-dried wood (Zhu et al. 2009; Zhu et al. 2010). With excellent cellulose conversion and very low

size-reduction energy consumption, SPORL fits the requirement for forest biomass conversion. SPORL

(a)

Conversion

Glucose yield

SPORL, bisulfite = 8%, acid = 3.68%

Dilute acid, acid = 3.68%

OrganoSolv-B (pan 2005)

OrganoSolv-A (pan 2005)

Red pine

Red pine

Mixed softwood

Mixed softwood

100

100

80

80

60

60

40

40

20

20

0

10

20

30

40

50

Enzymatic hydrolysis time (hour)

(b)

100

100

80

80

60

60

40

40

ECCS

EHGY

pH

4.46 0

0.92

1.84

Organosolv (pan 2006)

Acid (%)

20

20

2.32

2.00

0

0

0

10

20

30

40

50

Enzymatic hydrolysis time (hour)

FIGure 15.6

Comparison of enzymatic hydrolysis cellulose conversion and glucose yield between sulfite

pretreatment to overcome recalcitrance of lignocellulose (SPORL) and the organosolv processes: (a) softwood

and (b) aspen.