Environmental Engineering Reference

In-Depth Information

Wood

chips

Impregnation

(optional)

Saccharification

Fermentation

Substrate

Filtration

Wa shing

Substrate

(alternative)

SSF

Spent

liquor

Hemicellulose

Steam/hot

water

Fermentation

Distillation

Liquor

preparation

Lignosulfonate

Ethanol

Base

(Na, Mg,

NH

4

, Ca)

Lignin residue

SO

2

generator

Heat/chemical

recovery

Steam/electricity

Sulfur/FeS

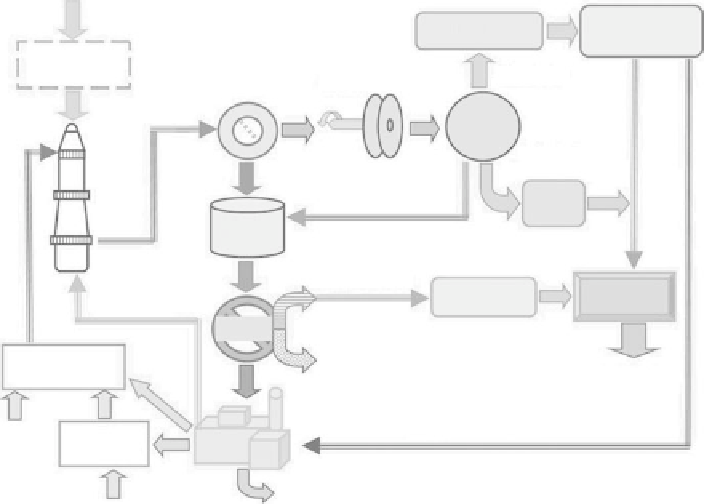

FIGure 15.5

A schematic process flow diagram of the SPORL.

15.6.2.3 sulfite Pretreatment—sPorl

The recently developed SPORL process (Wang et al. 2009; Zhu et al. 2009) is based on the funda-

mental understanding of sulfite wood pulping. The degrees of hemicellulose dissolution, cellulose

depolymerization, and lignin sulfonation and condensation are controllable by varying pulping con-

ditions, such as temperature and pH (Yorston 1942; Hall and Stockman 1958; Bryce 1980). By prop-

erly controlling reaction temperature, pH, and time, lignocellulose recalcitrance can be removed

through a mild sulfite pretreatment process.

A schematic process flow diagram of the SPORL is shown in Figure 15.5. Wood chips first react

with a solution of sodium bisulfite (or calcium or magnesium or other bisulfite) at 160-190°C and

pH 2-5 for about 30 min and then are fiberized using a disk refiner to generate fibrous substrate for

subsequent saccharification and fermentation. The removal of the recalcitrance of lignocellulose by

SPORL is achieved by the combined effect of dissolution of hemicelluloses, depolymerization of

cellulose, partial delignification (less than 30%), sulfonation of lignin, and increasing surface area

by defiberization through disk refining. Lignin sulfonation increased the hydrophilicity of SPORL-

pretreated substrates and may have promoted the enzyme processes. The pretreatment liquor to

biomass ratio is typically in a range of 2-3, significantly lower than that used in dilute acid and

organosolv processes. Therefore, SPORL can produce a relatively concentrated hemicellulose sugar

stream. The dissolved hemicellulose stream (a mixture of hexoses and pentoses) can be further

fermented to ethanol. The fermentation of spent sulfite pulping liquor (SSL) has been in industrial

practice for commercial cellulosic ethanol production for decades (Helle et al. 2008). The dissolved

lignin sulfonate or five-carbon hemicellulose sugars can be used to produce value-added co-prod-

ucts that can be directly marketed and has been practiced in the industry. Therefore, SPORL has the

advantage of valuable co-product commercial pathways from dissolved hemicellulsoe sugars and

lignin, important to the economics of the process.

Typical pretreatment conditions of SPORL are temperatures of 170-190°C and pH 2-5. For labora-

tory batch operation, retention time is about 30 min. The bisulfite charge on biomass depends on the