Environmental Engineering Reference

In-Depth Information

Wood chips

Wood chips

Size

reduction

Size

reduction

~150-700 wh/kg wood

Saccharification

conversion

Saccharification

conversion

<50 wh/kg wood

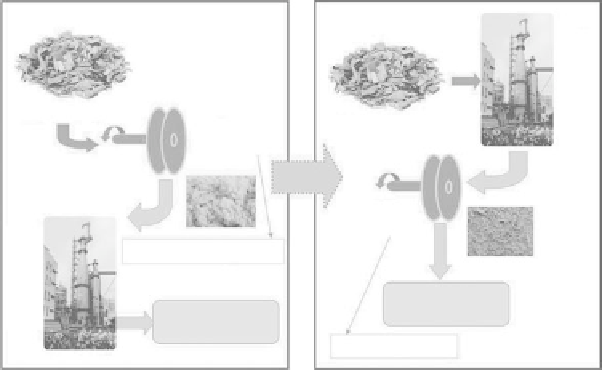

FIGure 15.4 (see color insert)

Required order for size reduction operation from pre- to postchemical

pretreatment to reduce energy consumption.

that post-chemical pretreatment size reduction is not only preferred (Figure 15.4) to take advan-

tage of chemical pretreatments for economical size reduction, but also necessary for the economical

biochemical conversion of forest biomass as discussed previously. Furthermore, different chemical

pretreatments alter biomass structure to various degrees and therefore affect post-pretreatment size-

reduction energy savings (Zhu et al. 2010). For example, the SPORL pretreatment (Zhu et al. 2009)

of wood chips is much more effective to reduce size-reduction energy consumption than the dilute

acid pretreatment conducted at the same pretreatment time, temperature, and acid charge conditions

(Zhu et al. 2010).

This post-chemical pretreatment size-reduction process flow design has several benefits: (1) it

takes advantage of chemical pretreatment to alter wood structure to reduce energy consumption in

the subsequent size-reduction process; (2) it avoids the difficulties and high-energy consumption for

mixing high-consistency pulp with chemicals in pretreatment when size-reduced substrate is used;

(3) it can reduce thermal energy consumption in chemical pretreatment; and (4) it can potentially

produce a concentrated hemicellulose sugar stream to reduce concentration cost. The rationale for

benefits 3 and 4 is that a lower liquid-to-wood ratio can be used in the chemical pretreatment of

wood chips than that in pretreatment of fiberized wood pulps. Liquid uptake of fiberized wood pulps

is much higher than that of wood chips because of the porous and hydrophilic nature of wood.

15.6.2 c

hEmical

p

rEtrEatmEnt

of

f

orESt

B

iomaSS

Existing enzymes cannot effectively convert lignocellulose to fermentable sugars without chemi-

cal pretreatment. Few pretreatment technologies are capable of effectively removing recalcitrance

of forest biomass, especially softwood, to achieve satisfactory cellulose conversion to glucose.

Because of the large amount of energy required in size reduction for forest biomass, a viable pre-

treatment process for forest biomass needs to be not only effective in removing recalcitrance but

also capable of doing so before wood size reduction (i.e., on wood chips, not on fiberized materials).

This makes pretreatment of forest biomass much more difficult than and different from agriculture

biomass, which has not been well recognized by the research community. The most studied and

currently widely adopted process in commercial demonstration (i.e., dilute acid process) developed

a century ago has been shown to be ineffective for almost all wood species. Acid-catalyzed steam

explosion, organosolv, and sulfite pretreatment to overcome recalcitrance of lignocellulose (SPORL)

(Zhu et al. 2009) are the only three processes that have demonstrated effectiveness for forest bio-

mass bioconversion.