Environmental Engineering Reference

In-Depth Information

yellow. Maturity is attained 90 days after flowering (Heller 1996). Because all of the fruits do not

mature at the same time, they have to be harvested manually at regular intervals, making this opera-

tion very labor-intensive (Heller 1996; Singh et al. 2006). The time and length of the harvest period

is likely to vary according to the seasonal conditions of the locality. In semiarid regions, the har-

vesting spans over a period of two months, which implies daily or weekly harvests. In permanently

humid situations, weekly harvest is necessary throughout the year. Separation of the seeds from the

husks can be done manually or mechanically (Gour 2006).

Apparently, the yield depends on a range of factors such as water availability, soil conditions,

altitude, sunshine hours, and temperature. No systematic research seems to have been conducted

yet to determine the influence of these factors and their interactions on seed yield. The seed yields

reported for different countries and regions range from 0.4 to over 12 t/ha per year after 5 years of

growth (Jones and Miller 1992). In relatively poor soils, the yields have been reported to be 1 kg per

plant, whereas in lateritic soils the seed yields have been reported as 0.75

-

1.00 kg/plant (Openshaw

2000). Thus, the average yield can be considered as 4.00-6.00 t/ha per year depending on the

agroclimactic zone and agricultural practices (Biswas et al. 2007). Harvesting of the seeds takes

place during the dry season, which is normally a quiet period for agricultural laborers. The ripened

fruits are plucked from the trees manually, and the seeds are sun-dried (three weeks) or oven-dried

(105°C) to reduce the moisture content up to a certain level. The dried pods are collected, and the

seeds are separated manually or mechanically. Seeds are once again dried under sunlight for four

days until the moisture reaches approximately 6-10% before oil extraction. Drying of seeds is

necessary because moist seeds can develop mold and can jam the pressing equipment.

14.3.4 o

il

E

xtraction

m

EthodS

The seeds contain on an average approximately 34% oil. The oil contains a toxic substance, cur-

casin, which is a strong purgative (Chachage 2003). To prepare the kernels for oil extraction, they

should be solar heated for several hours or roasted for 10 min. This process breaks down the cells

containing the oil and eases the oil flow. The heat also liquefies the oil, which improves the extrac-

tion process. The seeds should not be overheated. The oil from jatropha seeds can be extracted by

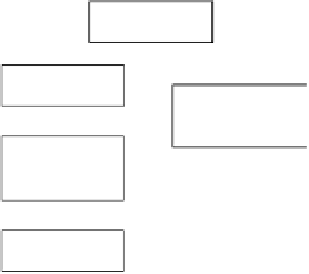

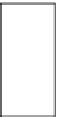

mechanical extraction using a screw press or chemical extraction (solvent extraction). Figure 14.2

Oil extraction

methods

Chemical

methods

Mechanical

methods

Seed in

hopper

Seed

kernel

Keeping the

solution in beaker

for 24 hours

Manual/

mechanical

grinding

Seed

grinder

Filtering

Pressing grinded

seed

JCL paste mixed

with CCL

4

Shaking for

72 hours

Oil

production

Oil

Cake

Jatropha oil

FIGure 14.2

Flowchart for mechanical and chemical methods of oil extraction.