Environmental Engineering Reference

In-Depth Information

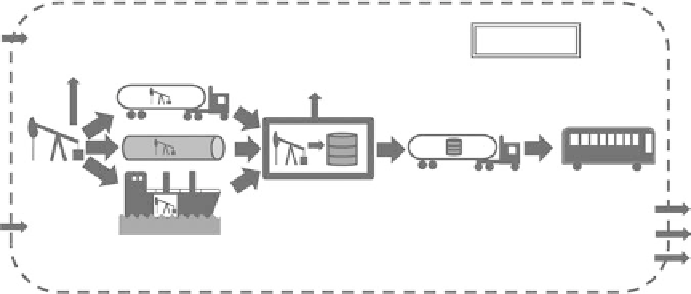

System boundary

Coproducts:

Gasoline

Heavy fuel oil

Jet fuel

Petroleum coke

Asphalt

Energy

resources

examples:

Crude oil

Natural gas

Electricity

Coal

Petroleum diesel

life-cycle model

Coproducts:

Natural gas

Production:

Foreign and

domestic crude

oil

Transport:

Diesel to distribution

Urban bus operation:

Diesel

Refining:

Crude oil to diesel

GHGs/air

emissions

Water emissions

Solid waste

Material

resources

examples:

Limestone

Metals

Water

Transport:

Crude oil to

U.S. refineries

FIGure 11.6

Life-cycle of petroleum diesel for use in an urban bus. (From Sheehan, J., et al., Life cycle

inventory of biodiesel and petroleum diesel for use in an urban bus. NREL/SR-580-24089, National Renewable

Energy Laboratory, Golden, CO, 1998.)

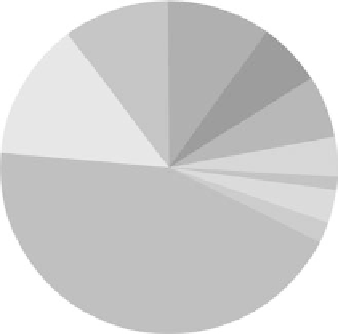

Diesel oil

(other)

10.1%

Jet fuel

9.95%

Heavy fuel oil

6.17%

Petroleum coke

6.04%

Diesel oil

(low-sulfur) 13.4%

Asphalt

3.83%

Lubricants

1.30%

Petroleum feedstocks

3.19%

Gasoline

44.0%

Other

2.0%

FIGure 11.7

Petroleum diesel refinery products, by mass. (From Sheehan, J., et al., Life cycle inventory

of biodiesel and petroleum diesel for use in an urban bus. NREL/SR-580-24089, National Renewable Energy

Laboratory, Golden, CO, 1998.)

domestic sources. All crude petroleum was transported to diesel refineries in the United States.

This assumption is fair, given that only 4% of petrodiesel entered the United States in a refined state

at the time of this study. On average, foreign crude traveled 7 times farther than domestic crude.

Transportation of foreign crude was 4 times more primary energy-intensive (1.09 MJ/kg for foreign

vs. 0.27 MJ/kg for domestic), mainly attributed to tanker ship transportation.

The refinery model was based on U.S. average data. Over 90% of the refinery's energy was sup-

plied by the crude petroleum entering for conversion to diesel. Refinery products and co-products

are shown in Figure 11.7. This study assumed low-sulfur diesel will be used by the bus. One problem

with the mass allocation method is that it does not identify refinery inputs uniquely required for

diesel production (e.g., a chemical input exclusively needed for diesel production) and specifically

assign their burdens to the diesel fuel. This allocation method may be selected when detailed sub-

process data are not available.

11.2.2.2.2

Biodiesel Model

The Kim and Dale (2005) ethanol study discussed earlier considered the dominant corn-soybean

crop rotation system, but Sheehan et al. (1998) focused solely on soybean production over one grow-

ing season (per year) with no crop rotations. Energy and emissions related to production of capital