Environmental Engineering Reference

In-Depth Information

by a factor of 10 in PM (from 0.1 to 0.01 g/bhp-h) and NO

x

(from 2 to 0.2 g/bhp-h), respectively

(U.S. EPA 2010g). In the case of diesel CI engine combustion, there is an inherent NO

x

-soot tradeoff

that is based on the temperature-equivalence ratio path that combustion follows, making emission

control difficult. To meet the 2007-2010 standards, diesel engines now incorporate complex after-

treatment systems that typically include an oxidation catalyst, a continuously regenerating PM trap,

and a lean NO

x

reduction system such as a selective-catalyst-reduction/urea system.

Evaporative emissions are those that can come from fuel in storage tanks during various drive

and park cycles and as a result of refueling the vehicle. These, in addition to the tailpipe emis-

sions outlined above, have been regulated for gasoline-fueled vehicles because of the fuel's high

volatility. Evaporative emissions are composed of light volatile organic compounds (VOCs) in the

fuel and cause ground-level ozone problems and human health issues (U.S. EPA 2007b; de Nevers

2000). Tier 2 evaporative emission standards for LDVs include a three-diurnal test combined with

a hot soak (after engine operates above ambient temperatures and is shut down) along with running

losses, being 0.50 g/test and 0.05 g/mi for LDVs in model year 2009 (U.S. EPA 2009).

To maintain these standards, vehicles must include on-board-diagnostic (OBD) systems to con-

tinuously monitor all components that would result in the failure of the vehicle to meet these stan-

dards. If a failure occurs, a diagnostic check engine light informs the driver of a problem and

diagnostic codes on the faulty component(s) are stored and used for servicing purposes.

10.2

Ic enGInes

10.2.1 B

aSic

E

nginE

o

pEration

The IC engine has existed since the 19th century, when pioneers including Jean Lenoir, Nicholas

Otto, and Rudolf Diesel proved that the concept of a heat engine relying upon IC was a viable mech-

anism (Cummins 1989). An IC engine is a mechanical device that converts energy contained within

chemical bonds in the fuel into kinetic energy in the form of a rotating shaft that can be used to do

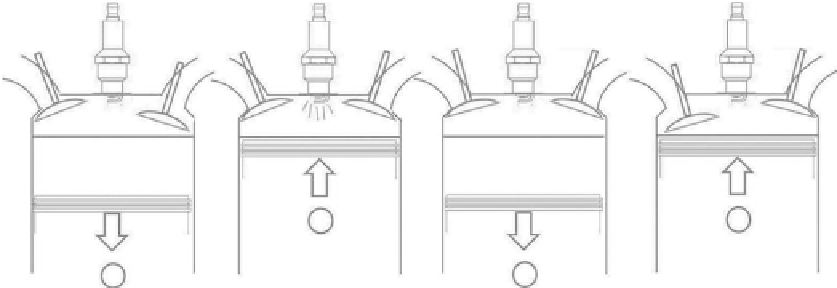

useful work. The four-stroke cycle engine, which is used in nearly all transportation vehicles, con-

sists of a piston moving up and down within a cylinder inside of the engine. The piston is connected

to a crankshaft; thus, the reciprocating motion of the piston is translated via the connecting rod and

crankshaft into rotational kinetic energy at the shaft. The engine operates on a cycle, wherein the

piston makes four distinct strokes of the cylinder over two revolutions of the crankshaft as shown in

Figure 10.6. These four strokes are described as follows:

Exhaust

Intake

Exhaust

Intake

Exhaust

Intake

Exhaust

Intake

Intake stroke

Piston moves down,

induct charge;

Cl - air + residuals

Sl - air + fuel

Compression stroke

Piston moves up,

compress gases;

Sl - spark plug fires

Cl - fuel injection

Expansion stroke

Piston moves down by

force of combustion gases.

Useful work output.

Exhaust stroke

Piston moves up, exhaust

gases pushed out of cylinder

FIGure 10.6

Four-stroke engine operating cycle. SI engine shown with spark-plug for ignition.