Environmental Engineering Reference

In-Depth Information

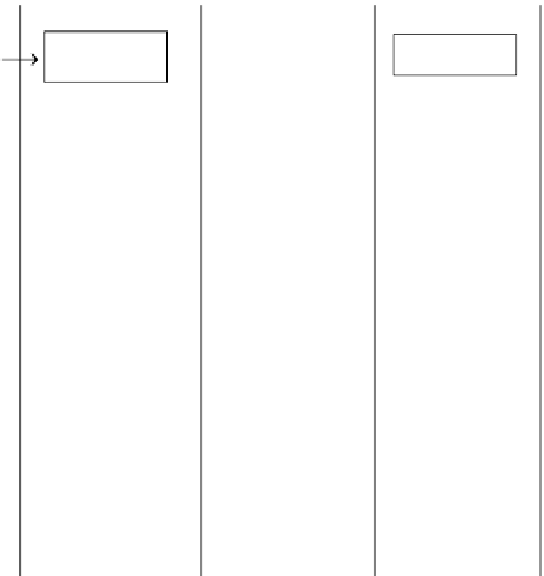

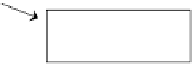

Conventional biofuels

Biochemical

Corn,

Enzymatic

hydrolysis

Glucose,

sucrose

Ethanol,

DDGS

sugar beets

Fermentation

sugar cane

Thermochemical

Triglycerides:

soybean, rape

seed, palm

Biodiesel,

glycerol,

soymeal...

Solvent

extraction

Transester-

ification

Plant bio-oil

Advanced

biofuels

Biochemical

Lignocellulosic

feedstocks

Glucose

xylose

galactose

arabinose

mannose

Enzyme

hydrolysis,

fermentation

Ethanol,

butanol,

hydrocarbons

Chemical

hydrolysis

Thermochemical

Triglycerides:

camelina, algae,

tallow, jatropha

Hydrocarbon

biofuels

Solvent

extraction

Hydrotreatment

Bio-oil

Gasification

Synthesis gas

Fischer-tropsch

Lignocellulosic

feedstocks

Hydrocarbon

biofuels

Pyrolysis,

hydropyrolysis

Py-oil

HydroPy-oil

Hydrotreatment

Biomass

Pretreatment

Intermediates

Conversion

Biofuels

FIGure 8.1

Processing routes for conventional and advanced biofuels.

advanced biofuels. In both cases, biomass feedstock is first converted into an intermediate product

through initial reaction or separation steps. The intermediates are then transformed to final biofuel

product and co-products through additional reaction and separation steps. The vast majority of global

production is conventional biofuels [2008 data, 18.7 billion gallons ethanol/year, 4.4 billion gallons

biodiesel/year (EIA 2010)]. Dry and wet mill corn ethanol facilities produce an intermediate glucose

sugar product and a final product of ethanol plus dry distiller grains solids (DDGS), which is marketed

as an animal feed. The overall fermentation reaction is given by C

6

H

12

O

6

→ 2 C

2

H

5

OH + 2 CO

2

.

Two carbons from the sugar molecule are emitted as carbon dioxide, but the energy content of the

two ethanol molecules is substantially higher than the sugar feedstock. Process energy for corn

ethanol production is typically from natural gas for steam production and electricity is from the local

grid. Because of the importing of these energy resources, corn ethanol has a relatively large fossil

energy demand (ratio of fossil energy required for all processing steps per unit of energy in ethanol

produced) of approximately 0.5-0.8 (Wu et al. 2006; Shapouri et al. 2010). Current (as of 2010)

production rates of corn grain ethanol in the United States are approximately 50% that of global

production at 12 billion gallons/year (RFA 2010), and from sugar cane in Brazil it is approximately 8

billion gallons ethanol/year (EIA 2010). Biodiesel is a methyl ester of fatty acids derived from plant

oils. The biodiesel reaction can be simply described as triglyceride + methanol → 3 fatty acid methyl

esters + glycerol (CH

2

OH-CHOH-CH

2

OH). Methanol is almost always produced from natural gas

(fossil origin), and co-products of biodiesel production include glycerol and a residue from the oil

extraction step (soymeal for example), which is often marketed as animal feed. The key intermediate

is a plant oil obtained from the oil extraction step.

Advanced biofuels take advantage of the most plentiful biomass resource on Earth, lignocellulosic

(woody) feedstocks, and of unconventional plant oils and algae. Processing routes for advanced