Environmental Engineering Reference

In-Depth Information

compounds, such as PCBs and some pesticides, and an

example of soil excavation is shown in Figure 5.19. The

costs associated with excavation and removal of large

volumes of soil to another site are usually high, and on-

site treatment of soils, called

ex situ treatment

, should

always be considered as an option. On-site (ex situ)

treatment usually involves processes to remove the

contaminant(s) from the soil and replace the treated soil

at the site. Ex situ treatment techniques include soil

washing, biomounding, low temperature thermal desorp-

tion, and high temperature incineration. For large quan-

tities of contaminated soil, a common reclamation

method involves soil excavation and deposition in a

bioreactor, where biodegradation of the contaminant is

achieved in a comparatively short period of time. This

requires controlling the appropriate supply of moisture,

oxygen, and nutrients for the enhancement of microor-

ganism development and growth. Total excavation of

contaminated soils is sometimes not practical, such as

when contamination penetrates deep into the subsur-

face, contaminants occur beneath a building, or nAPLs

are present.

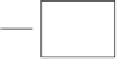

5.8.2.3 Soil Vapor Extraction.

Soil vapor extraction

(SVE) systems are designed to maximize contaminant

removal by volatization. These systems extract air from

the vadose zone with blowers or vacuum pumps, and

treatment systems above ground remove toxic vapors

from the extracted air. SVE systems are frequently used

to remove volatile contaminants from permeable soils

and are analogous to pump-and-treat systems for

groundwater. A schematic diagram of a SVE system is

shown in Figure 5.20a, and a typical aboveground view

of vapor extraction pipeline as it exits the ground is

shown in Figure 5.20b. In spills of complex solvent mix-

tures, such as gasoline, SVE removes the components

with higher vapor pressures first. The advantages of

using an SVE system are that it creates minimal distur-

bance of the contaminated soil, it can be constructed

from standard equipment, it is cost-effective, and it is

flexible in that several variables can be adjusted during

design or operation. Extraction wells are typically

designed to fully penetrate the vadose zone and to

extend below the water table. Penetration of the water

table allows for seasonal declines in the water table

elevation and declines caused by pumping. Extraction

wells typically consist of an upper 1.5 m (5 ft) of solid

plastic casing connected to slotted plastic pipe placed in

permeable packing. The borehole is typically augured

and sealed around the casing to the top of the borehole

Figure 5.19.

Soil excavation at a Superfund site.

Source

: U.S.

Army Corps of Engineers (2005b).

off-gas

treatment

g

round surface

air flow

air flow

contaminated

soil

water

table

(a)

(b)

Figure 5.20.

Soil vapor extraction system. (a) Schematic diagram of SVE system; (b) aboveground view of vapor extraction

pipeline.

Sources

: U.S. Air Force (2005); nevada Division of Environmental Protection (2012).

Search WWH ::

Custom Search