Environmental Engineering Reference

In-Depth Information

Step 2.

Conduct a soil sample analysis to determine

the fraction,

f

oc

, of organic carbon in the soil, the

bulk density,

ρ

b

, of the soil, the water-filled poros-

ity,

θ

w

, and the concentration,

c

s

, of organic com-

pound in the saturated soil (typically in mg/kg).

Step 3.

Calculate the theoretical pore water concen-

tration,

c

w

, assuming no nAPL, where

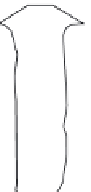

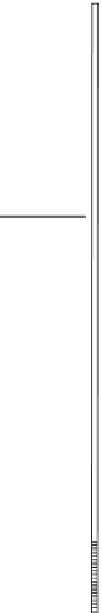

5.7 MONITORING WELLS

monitoring wells are essential components of all sub-

surface investigations involving the saturated zone, and

the proper design of monitoring wells is a prerequisite

for obtaining representative measurements of ground-

water quality. A typical monitoring well is illustrated in

Figure 5.12. monitoring wells basically consist of a per-

forated pipe (called the screen or intake) attached to a

solid pipe (called the

casing

or

riser

) installed in a drilled

borehole. The annular region between the well and the

borehole is filled with sand or gravel (called the gravel

pack) up to a level just above the screen, capped with a

sealant, and backfilled with grout to the ground surface.

General specifications for monitoring wells are given

below.

c

f K

ρ

s b

c

=

(5.84)

w

ρ

+

θ

b oc

oc

w

Step 4.

Compare

c

w

with the effective solubility,

c

0

,

such that if

c

w

>

c

0

, the presence of residual nAPL

is indicated.

EXAMPLE 5.17

Drilling.

monitoring wells in unconsolidated materi-

als are frequently installed using

hollow-stem

augers

, which are rotated into the ground to bring

up soil and create the boring. A typical hollow-

Analysis of a soil sample indicates 150 mg/kg benzene,

2% organic carbon in the soil matrix, a bulk density of

1800 kg/m

3

, and a water-filled porosity of 0.29. If the

benzene in the soil is a result of a gasoline spill, where

the gasoline contains a mole fraction of 1.5% benzene,

determine whether gasoline is present as an nAPL in

the soil. In accordance with Raoult's law, the maximum

concentration of benzene in groundwater can be taken

as the mole fraction of benzene in gasoline multiplied

by the solubility of pure benzene in water.

Well

identification

labeled

Vented cap

Protective casing

Drain hole

Protective cover

Concrete pad

Solution

From the given data,

c

s

= 150 mg/kg = 1.5 × 10

−4

kg/kg,

f

oc

= 2% = 0.02,

ρ

b

= 1800 kg/m

3

, and

θ

w

= 0.29. Appen-

dix B.2 gives

K

oc

= 10

1.92

= 83.2 cm

3

/g = 0.0832 m

3

/kg,

and the solubility of pure benzene is 1780 mg/L. Since

the spilled gasoline contains 1.5% benzene, the effec-

tive solubility of benzene derived from gasoline is

0.015(1780) = 26.7 mg/L. According to Equation (5.84),

the theoretical pore water concentration,

c

w

, assuming

no nAPL, is given by

Casing

material

Dry bentonite

pellets

Grout

Riser material

Centralizers

c

f K

ρ

Grout

s b

c

w

=

ρ

+

θ

Secondary

filter pack

b oc

oc

w

1 5 10 1800

1800 0 02 0 0832

( .

×

−

4

)(

)

=

(

)( .

)( .

)

+

0

.

29

Bore hole

Bentonite

seal

8= mg/L

Secondary

filter pack

Since

c

w

exceeds the solubility of benzene in water

(= 26.7 mg/L), the presence of of gasoline nAPL is

strongly indicated.

As a rule of thumb, if the hydrocarbon concentration

in the soil matrix exceeds 10,000 mg/kg (1% of soil

mass), the sample probably contains some nAPL

(Cohen and mercer, 1993; Feenstra et al., 1991).

Centralizers

Primary

filter pack

Well screen

Plug

Figure 5.12.

Typical monitoring well.

Search WWH ::

Custom Search