Environmental Engineering Reference

In-Depth Information

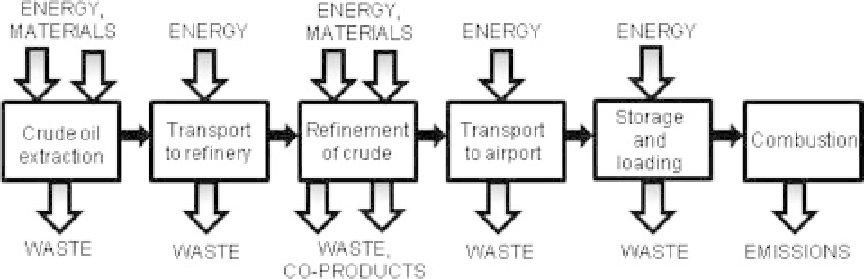

Figure 11.16. Schematic of life cycle assessment for conventional petroleum fuel.

If we want to compare the change in greenhouse gas emissions due to changing from conven-

tional jet fuel to an alternative fuel while flying a fully loaded Boeing 787 fromNewYork toTokyo,

we might choose grams of CO

2

emissions per kg fuel (g CO

2

/kg). If we know howmany kilograms

of fuel are burned on such a trip, we can calculate the mass of CO

2

emitted during this flight. For

this case, everything in the problemmust be converted to something representing the mass of CO

2

that is emitted for every kg of fuel that is burned. This becomes a little tricky, because we know

that CO

2

is not the only greenhouse gas of interest, and we would like to include the effects of other

emissions. Most environmental LCAs incorporate other greenhouse gas emissions by introducing

the concept of equivalent CO

2

emissions (CO

2,eq

). The equivalence is developed through conver-

sion factors, such as global warming potential (GWP) or alternatively radiative forcing (RF), which

account for the manner in which the pollutant affects the buildup of heat in the atmosphere. When

the mass of the greenhouse gas is multiplied by its corresponding conversion factor, the result is

in units of g CO

2,eq

, and we can sum the effects of all of the greenhouse gases to find a number

that represents the mass of CO

2

equivalent that was pumped into the atmosphere by the flight.

Knowing something about the chemistry of the fuel combustion process, the aircraft perfor-

mance and operating conditions, it may be relatively straightforward to estimate how much CO

2

,

CO, NO

x

,SO

x

,H

2

O, and particulate matter is created by burning a kilogram of jet fuel. The really

tricky part is that we would also like to include the entire history of CO

2

-equivalent emissions

that were generated by manufacturing that kilogram of fuel. So now we have to back up and look

at the process that brought us this jet fuel.

The life cycle of conventional fossil fuel is depicted in Figure 11.16. The LCA must capture

the environmental impact of all of the materials and processes that are required to create aviation

fuel, as well as all of the things that are left behind after each step of the process is performed. In

the simplest type of analysis, each of these things is expressed in terms of our functional units.

It may not be immediately obvious how to do that, but let us begin by identifying all of the stuff

along the life cycle path.

The first step is to extract the crude oil, noting all of the energy and materials needed to

perform this step, such as chemicals, lubricants and water or other coolants used for drilling.

We must also take care in identifying all of the waste that is generated during the extraction.

For example, there will be gaseous emissions associated with using fuel to power machinery.

Next, the crude oil is transported to the refinery in a pipeline, in a supertanker, by truck and/or

by rail. Each of these modes of transport requires energy (e.g., fuel to run motors or pumps) and

generates waste (e.g., gas emissions). At the refinery, the crude oil is processed to yield aviation-

grade fuel. Inputs for this step include electricity and/or fuel to heat reaction chambers and pump

fuel through distillation columns, as well as the environmental cost of input gases, chemicals,

and catalysts. Crude oil is a mixture of organic hydrocarbons, only some of which are suitable

for aviation fuel. The remaining (non-aviation) fuel can be sold for other purposes and would

be considered a co-product of the refining process. Co-products are materials, energy, or other

Search WWH ::

Custom Search