Environmental Engineering Reference

In-Depth Information

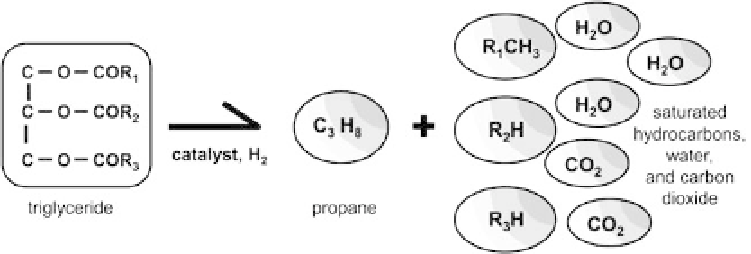

Figure 11.15. An example of hydrotreatment: deoxygenation of a triglyceride into saturated hydrocarbons,

water and carbon dioxide.

There are trade-offs to be made here. The isomerisation process is similar to the deoxygenation

reaction described above in that it operates at moderate temperatures (perhaps 250-350

◦

C) and

pressures (typically less than 5MPa). It uses excess H

2

and catalysts as reactants, and it will

produce the most jet fuel when the feedstock molecules are in the range of C10-C14. If the

feedstock has carbon chains that are either shorter or longer, the resulting hydrocarbon mix can

undergo fractional distillation to separate out the heavier and lighter hydrocarbons. The less

desirable components can be used for other purposes, such as green diesel or cooking fuel, but

it will supply less jet-grade fuel. Isomerisation is also more effective when the feedstock is not

fully saturated.

For the case of vegetable oil that is heavily weighted in the C16-C18 range and/or is fully

saturated, the more extreme hydrocracking option can be considered. At higher temperatures

(

350-420

◦

C), much higher pressures (7-14MPa), excess H

2

, and the right catalyst, the carbon-

to-carbon bonds of long-chained

n

-paraffins are ripped apart to form shorter

n

-paraffins and

branched isoparaffins. The resulting product will have a higher proportion of hydrocarbons in the

range needed for jet fuel, but, due to the large energy input, it will come at a cost, both in terms

of fuel cost and in environmental impact.

For a good reference on hydroprocessing, seeRobinson andDolbear (2006); on hydrogenization

of unsaturated methyl esters, see Bouriazos

et al.

(2010). Refining vegetable oils removes most of

the natural antioxidants such as tocopherols (Holser and Harry-O'Kuru, 2006). For a discussion

of additives and blending to improve cold-flow properties see Chastek (2011), Coutinho

et al.

(2010), Joshi

et al.

(2011), Kerschbaum and Rinke (2004), Kerschbaum

et al.

(2008), Moser

(2009), Wang

et al.

(2011) and emissions see Moser (2009).

∼

11.5.4

Other strategies

Another option for creating jet fuel is to start with relatively low-weight alcohols, such as butanol,

and perform an oligomerization step. In this reaction, the short-chained hydrocarbons undergo a

reaction to extend the length of the hydrocarbons, thus building up from C3 towards jet fuel range

hydrocarbons.

Some studies have examined the use of microbes to produce these compounds directly from

sunlight (Atsumi

et al.

, 2008; Tan

et al.

, 2011), fatty acid feedstocks (Dellomonaco

et al.

, 2010)

or through fermentation of sugars from lignocellulosic decomposition (Ha

et al.

, 2010). This

technology is still in the early stages and is not a near-term solution.

11.5.5

Co-products

One of the most critical aspects of sustainable process development and economic viability will

be the identification of value-added chemicals, energy, and materials from the remnants of the

Search WWH ::

Custom Search