Environmental Engineering Reference

In-Depth Information

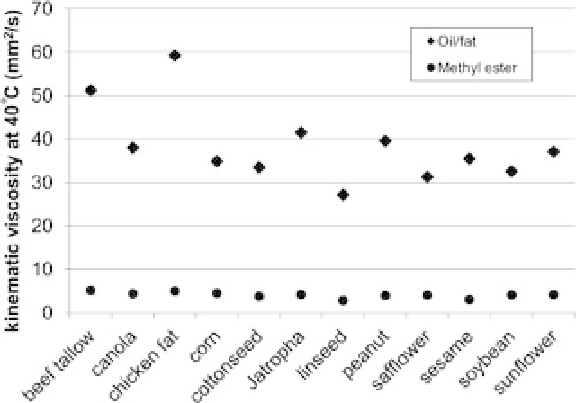

Figure 11.13. Transesterification reduces viscosity of vegetable oils and greases by conversion to methyl

esters. Data obtained from compilations in Jingura

et al

. (2010), Knothe (2008a), Lang

et al

.

(1992) and Refaat (2009).

apart the dense hydrocarbon chains to form smaller, highly branched hydrocarbons, shorter-chain

n

-paraffins, and a small amount of cycloparaffins (section 11.5.3). As a result, the molecular

makeup of HEFA is very similar to conventional jet fuel with a blend of pure hydrocarbons in the

range of C9-C15 (see Fig. 11.7i).

11.5.1

Dewatering, crude oil extraction and pre-processing

To prepare for refining, oil-rich beans or seeds are dried, cleaned, cracked and compressed into

flakes. The oil is extracted chemically by exposing it to a solvent or, less efficiently, mechanically

through pressing. A combination of pre-heating and mechanical extractions can increase oil

yield (Mahmoud, Arlabosse and Fernandez, 2011). For algae, the choices become more varied.

The algal biomass can be dried and oil extracted by chemical, biochemical and thermochemical

approaches, often with some mechanical assistance.

Dewatering can be an energy-intensive stage in oil production from algae. Even at the end of

a growth cycle, the algal broth is about 5-17% biomass in industrial-scale open ponds. Although

the biomass concentration could be much higher when grown in photobioreactors, there is still

significant water content. The biomass can be removed by a number of methods, such as sedimen-

tation, flotation, filtration, or centrifugation. The size and density of the algal cells are a primary

consideration for choosing a separation technique. Most algae cells are heavier than water, so sed-

imentation is one possible, inexpensive strategy, but it is slow and is better for large, dense cells,

roughly those larger than 50-100

µ

m. Many of the most promising algae for biodiesel production

are about 1-30

m in size. Flocculants reduce or neutralize the negative charge of microalgae so

that they can form clumps, which effectively increase the particle size for better sedimentation.

Flocculants, sometimes coupled with ultrasonic forcing, may be used as a pre-treatment step to

encourage clumping. In flotation, air is bubbled up through the culturing system. As algae (or

algae clumps) attach to the bubbles, they are carried up to the liquid surface, where they can

be removed by skimming. Membrane microfiltration is highly efficient at separating water from

biomass in small batches (Zhang

et al.

, 2010), but it is not a good fit for large-scale produc-

tion due to high energy requirements for pumping and filters that require lots of attention and

maintenance. Centrifugation is also very efficient in the lab, but it is prohibitive in an industrial

setting due to the high energy costs of running this equipment. If the biomass needs to be dried

for oil extraction, techniques range from the low-tech, slow process of drying in the sun to fast,

expensive processes such as bed drying, freeze drying, drum drying, and spray drying.

µ

Search WWH ::

Custom Search