Environmental Engineering Reference

In-Depth Information

Table 10.4. Estimated internal rate of return (IRR) and payback time (Source: Ekbom

et al

., 2005).

Methanol

DME

Additional investment cost

a

[million euro]

174

190

Total incremental operation cost

[million euro/year]

66.3

66.1

Production capacity

b

[million m

3

/year]

0.26

0.24

Cost of production

c

[euro/liter]

0.26

0.27

Selling fuel price

[euro/liter]

0.51

0.62

Profit

[euro/liter]

0.25

0.35

Profit

[million euro/year]

66.5

82.3

Payback

[years]

2.6

2.9

Internal rate of return (IRR)

[%]

40

45

a

The recovery boiler requires total investment

171 million euro

b

Production capacity equivalent to gasoline and diesel in m

3

c

Annuity factor (%)

=

=

11.1.

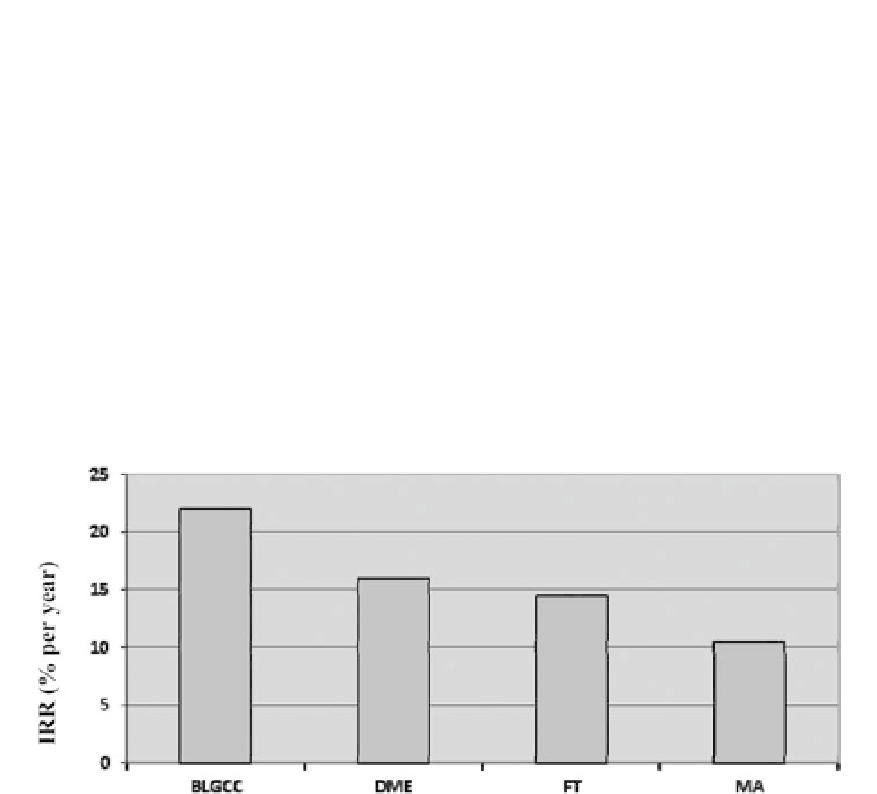

Figure 10.6. Estimated internal rate of return (IRR) of different biorefinery configurations (Source:

Consonni

et al

., 2009).

kiln for causticization using Chemrec black liquor gasification systems in the black liquor recov-

ery cycle for chemical recovery resulting in extra biomass utilization (Consonni

et al

., 2009). In

a conventional recovery system, sulfur is recycled as sodium sulfide whereas a large amount of

sulfur is recycled as hydrogen sulfide in the Chemrec system that results in about 25% increased

causticization load on the lime kiln. The increased biomass usage raises critical issues for future

biomass supply as the limited biomass will result in less availability of biomass to other processes.

The dry black liquor gasification (DBLG) system resolves this issue using direct causticization

within the gasifier eliminating the energy-intensive lime kiln in the recovery cycle.

The electricity deficit is an important system consequence of biofuel polygeneration. The

conventional recovery boiler system has a potential to export electricity after meeting the pulp

mill electricity demand (Table 10.2). However, biofuel polygeneration systems require electricity

to be imported from the grid or generated in biomass-based power plant.

The biofuel polygeneration systems using black liquor gasification indicate economic viability

since the economics of the pulp mill would be less sensitive to pulp prices, due to the diversified

overall economics of co-production of biofuels together with the pulp (Ekbom

et al

., 2005). The

internal rate of return (IRR) considering investment and operating cost of black liquor gasification

based methanol and DME production is presented in Table 10.4. Figure 10.6 shows internal

rate of return (IRR) results from another study (Consonni

et al

., 2009) estimated for different

biorefinery options e.g. Black liquor gasification combined cycle (BLGCC), dimethyl ether

(DME) production, Fischer-Tropsch (FT) liquid, mixed-alcohols (MA).

Search WWH ::

Custom Search