Environmental Engineering Reference

In-Depth Information

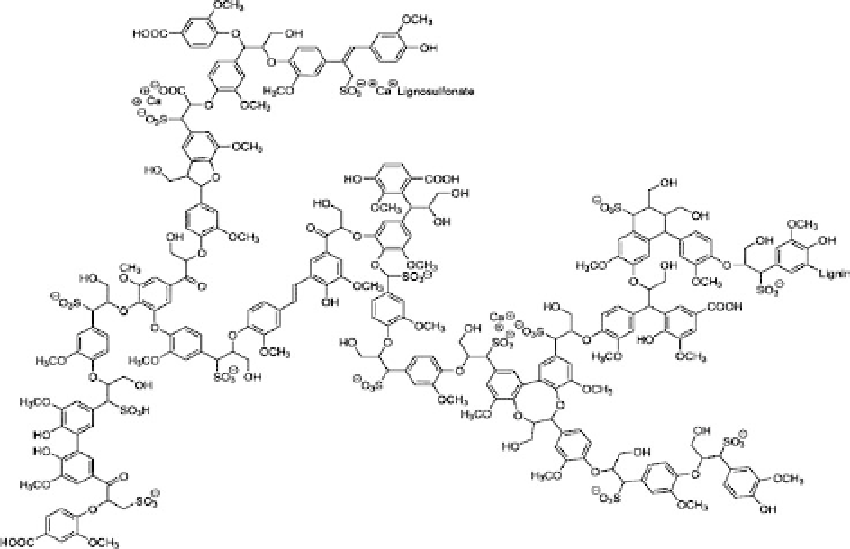

Figure 8.4. Structural representation of spruce lignosulfonate.

absolute rectified 99.5%). All grades are certified as kosher/pareve and are utilized in a wide

variety of applications, including biofuels, paints, solvents and pharmaceuticals.

8.2.4

Biomaterials, lignosulfonates

After fermentation and distillation, the remaining cooking liquor constitutes the raw material for

production of different lignin chemicals. At this point, the main components in the liquor are

sulfonated lignins, i.e. lignosulfonates, which are produced in the pulping process by hydrolysis

and sulfonation of the wood lignin. Due to the introduction of the highly hydrophilic, charged

sulfonate groups, the lignin is solubilized into the cooking liquor.

Lignosulfonates are highly complex aromatic polymers with multiple functionalities, including

phenolic and aliphatic hydroxyl, methoxyl, carboxyl and sulfonate groups (Fig. 8.4).When leaving

the fermentation plant, the cooking liquor is still a complex mixture, containing lignosulfonates

of different molecular weights, but also certain amounts of residual (C5) sugar components,

inorganic salts and insolubles.

In the lignin modification plant, this raw material is processed further by fractionation, purifi-

cation and chemical modification (e.g. oxidation and desulfonation) depending on the end use of

the product.

Due to their multifunctional nature, lignosulfonates have both dispersing, complexing and

binding properties, making them useful in a wide variety of applications. Looking into the history

of lignosulfonates, many current applications were also known 50 years ago. However, changes in

the customers' technologies, introduction of new technologies, competition from other products

etc. have changed the picture, and improvements and new lignosulfonate products have been

the result of the company's ongoing R&D efforts. The interest for lignosulfonate products is also

increasing since the products are produced from renewable resources, are environmentally friendly

and sustainable. Today the most important applications include plasticizers in concrete, binder

in animal feed pellets, extender in batteries, corrosion inhibitors in organic acids, dispersant in

Search WWH ::

Custom Search