Environmental Engineering Reference

In-Depth Information

Table 8.1. The 2009 world production of round wood.

Data from FAOSTAT (FAO Statistics, 2011).

Wood production

[million m

3

]

Wood fuel

1851

Sawlogs and veneer logs

782

Pulpwood, round and split

492

Other industrial roundwood

150

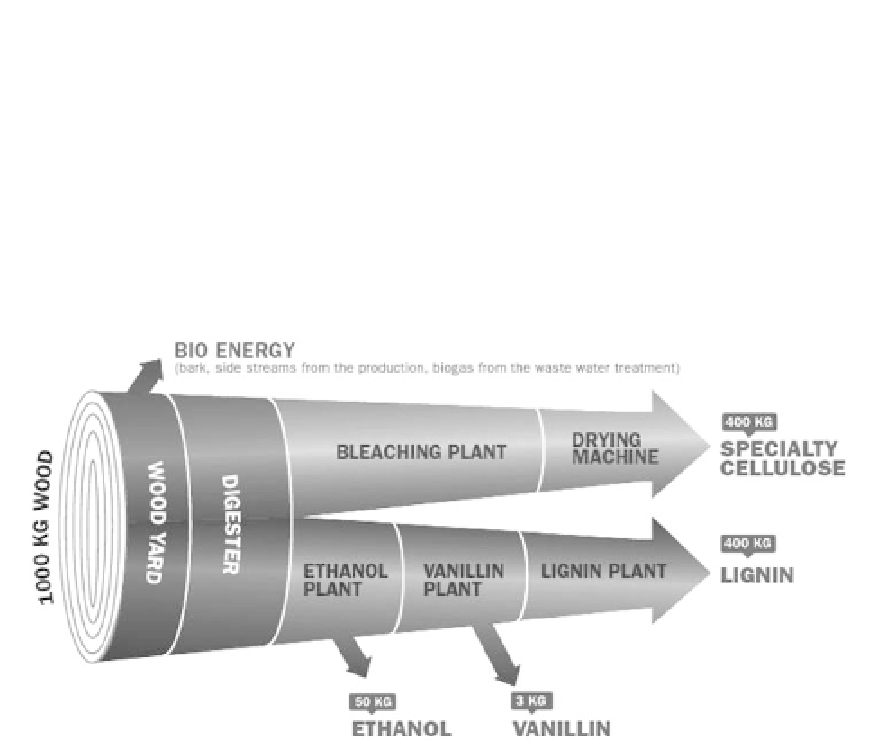

Figure 8.1. Schematic illustration of how wood is converted to marketable products at Borregaard.

removed lignin (sulfate lignin) has limited commercial value, and is usually incinerated in order

to recover energy and cooking chemicals. Some sulfate mills also isolate some of the extractives,

which are fractionated into fatty and resin acid constituents. In addition, turpentine (mixture of

monoterpenes) is produced.

In the less common sulfite chemical pulping process, the lignin in wood is dissolved from

the fibers using an aqueous solution of either sulfite (SO

2

3

) or bisulfite (HSO

3

) salts. The

counter ion, often referred to as the cooking base, can be either calcium (Ca

2

+

), sodium (Na

+

),

magnesium (Mg

2

+

) or ammonium (NH

4

). The sulfite process was initially developed around

the acidic calcium bisulfite process, for which neither recovery of cooking chemicals nor energy

production from lignin containing spent sulfite liquors (SSL) existed (Sixta, 2006). However, the

lignin fraction resulting from the sulfite pulping process, so-called lignosulfonate, has several

interesting properties (see section 8.2.4), making it an important raw material for a wide variety

of useful products.

Today, many different biorefinery concepts exist, the vast majority of which have the aim to

produce ethanol from biomass. Instead of listing and commenting on these current and future

projects, we have chosen to present a biorefinery concept that has been running for several decades.

This biorefinery, the Borregaard plant in Sarpsborg, Norway, is the most advanced biorefinery

operating today, and as such is a good example of a wood-based biorefinery.

The Borregaard Sarpsborg mill operates a calcium-based sulfite pulping process, in which the

high value wood components are extracted, while the less valuable components are used as fuel

(Fig. 8.1). The extraction of cellulose fiber, lignin, vanillin and ethanol is very efficient, leaving

only a small part of the wood to be converted to bio energy.

Search WWH ::

Custom Search