Environmental Engineering Reference

In-Depth Information

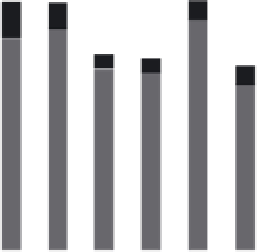

12 000

10 000

8 000

other

residential

industrial

6 000

4 000

2 000

0

1970 1975 1980 1985 1990

1995

2000 2005 2010

Figure 4.5. Charcoal use in Brazil 1970-2010 in 10

3

tonnes (EPE, 2011a).

but then, again exports were affected by the international economic recession. Thus, the use of

charcoal in Brazil varies in line with the conjunctures that affect the demand for metallurgical

products nationally and internationally, while other uses of charcoal have been quite stable.

Brazil is the ninth largest steel producer in the world. The production has increased continuously

in parallel with the industrialization of the country and demand in world markets. Today, Brazil

has installed capacity for production of more than 40 million tonnes of steel in both integrated

and semi-integrated plants - all certified according to ISO 14001 (IAB, 2010). Integrated and

semi-integrated plants are 27 in total, controlled by eight national and international business

groups, and located in ten different states in Brazil from north to south. In 2011, production

reached 32.5 million tonnes of which approximately two thirds were consumed internally and the

rest exported. Since 2009, these industries have developed greenhouse gas emissions balance.

According to IAB, the Brazilian steel association, only 5% of the iron reduction in these plants

is made with charcoal (IAB, 2011). However, these plants receive pig-iron from independent

producers where the use of charcoal is the most common. There is also an international market

for pig-iron.

The modern segments of the metallurgical industry in Brazil in the form of integrated and

semi-integrated plants contrasts with the often lower efficiency of pig-iron plants and the charcoal

production on which it is based. Large losses have been observed along the charcoal supply chain.

Some of the losses are gradually being used for the production of briquettes but there is still a

significant amount of waste. Research to develop charcoal kilns has been conducted continuously

but the implementation of more efficient technologies has been slow and uneven.

Reforestation aimed at charcoal production does take place, particularly articulated by the large

steel companies, which also use more efficient technologies. Nevertheless, charcoal production

has been traditionally decentralized in Brazil and largely based on the use of native forests and

traditional kilns. Large companies both produce and buy charcoal from small producers. The

cerrado

area, the second largest biome of the country, has been highly affected by this process.

Violation of environmental rules is still a problem also among the large international companies as

also indicated by the industry's sustainability report (IAB, 2010). Thus, forests are being planted,

but native forests are still being lost.

In the past years, forest-based industries including charcoal have been continuously discussed

in Brazil. Internationally, however, there has been very little interest in scrutinizing charcoal

production and use in Brazil. While there are companies organizing charcoal production in large

scale based on planted eucalyptus, a significant part of the production is decentralized, com-

ing from many small producers. The conditions of traditional charcoal production are socially

appalling. Approximately half of the wood source is illegal thus linked to natural forests. The

Search WWH ::

Custom Search