Biomedical Engineering Reference

In-Depth Information

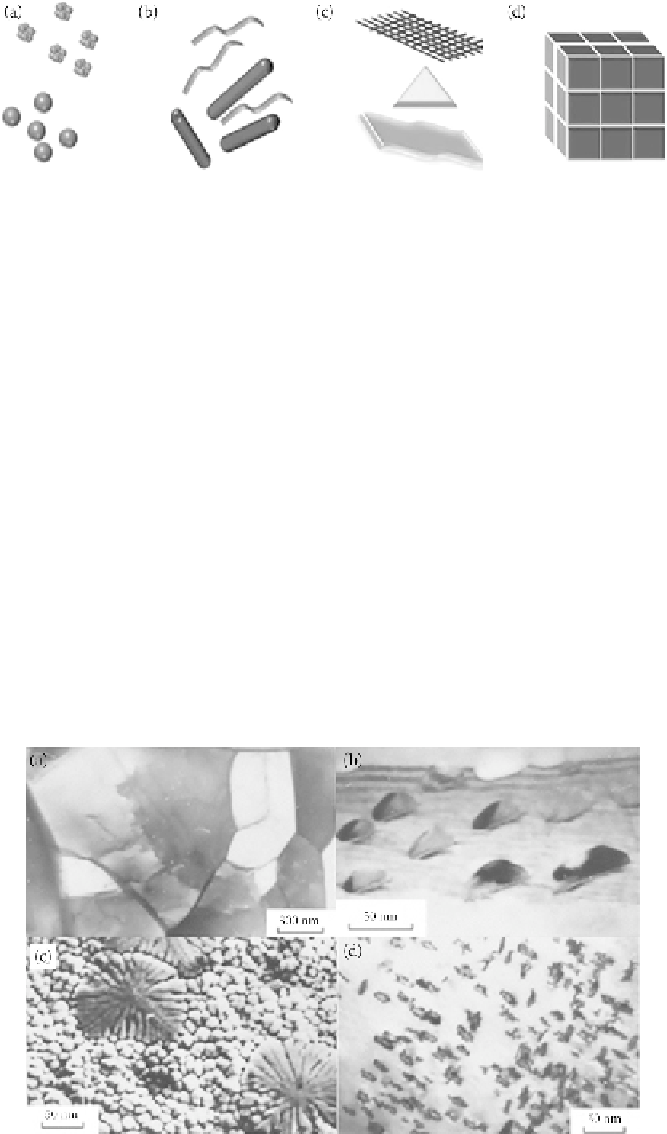

FIGURE 1.4

Classification of nanomaterials. (a) Zero-dimensional spheres and clusters. (b) One-dimensional

nanofibers, wires, and rods. (c) Two-dimensional films, plates, and networks. (d) Three-dimensional nanoma-

terials. (Reprinted with permission from Alagarasi, A. 2011.

Introduction to Nanomaterial

. National Centre

for Catalysis Research.)

NMs can be classified based on their phase composition properties, such as single-phase solids

(crystalline, amorphous particles, layers, etc.), multiphase solids (matrix composites, coated parti-

cles, etc.), and multiphase systems (colloids, aerogels, ferrofluids, etc.). Based on their methods of

manufacturing, NMs can be classified into three different categories: gas-phase reactions (flame

synthesis, condensation, etc.), liquid-phase reactions (sol-gel, precipitation, hydrothermal process-

ing, etc.), and mechanical procedures (ball milling, plastic deformation, etc.) (Wolfgang 2004). Based

on their structural properties, NMs can be classified into two parts: (1) nanocrystalline materials,

such as crystals, generally consisting of crystallite with at least one dimension in a nanometer size,

and (2) nanostructured materials, such as dislocation fragments, clusters, quasicrystals, micropores,

subgrains, and segregations. Nanofragmented materials, composed of dislocation fragments or sub-

grains whose size is less than 100 nm (Figure 1.5a), normally consist of metals and alloys subjected to

megaplastic deformations. Nonporous materials mainly exhibit a high volume density of nanopores

less than 100 nm situated on the conventional grain body or along their boundaries (Figure 1.5b).

Nanodendrites are materials mainly consisting dendrite solidification products in the form of degen-

erate dendrite nanodendrites, such as dendrite cells, and become visible upon the rapid solidification

FIGURE 1.5

Nanostructured materials. (a) Structure of nanofragmented material. Melts quenched FeSi

alloy, TEM. (b) Structure of nonporous materials. Nanopores are located at grain boundaries in a polycrystal-

line FeAl alloy produced by melt quenching, TEM. (c) Structure of nanodendrite materials. Dendrite nanocell

in side grain in a FeSi produced by melt quenching are visible, SEM. (d) Structure of nanodislocation materi-

als. Melt quench FeLi ally has high density of prismatic vacancy-type dislocation loop, TEM. (Reprinted with

permission from Glezer, A. M. 2011.

Russian Metallurgy (Metally)

4:263-269.)