Environmental Engineering Reference

In-Depth Information

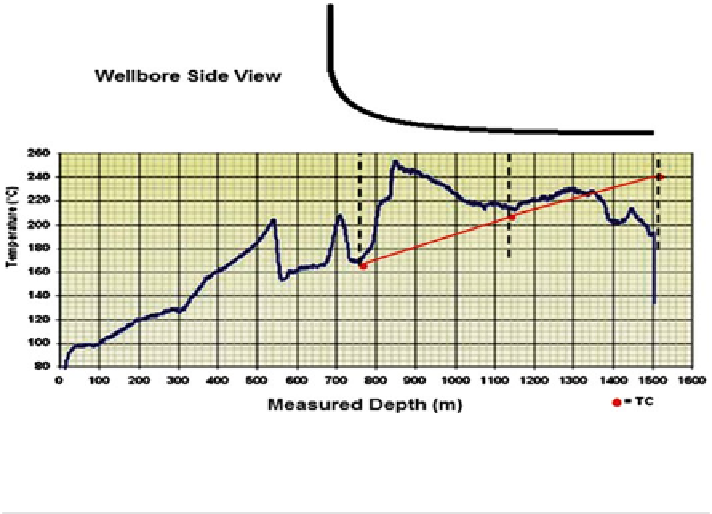

Thermocouple vs. DTS Measurements

An older technology used wired thermocouples placed at strategic points along a

wellbore in order to monitor temperature changes with time or as a result of produc-

tion, injection, or other stimulation or treatment. While such measurements are

accurate and are fairly inexpensive to install the results can sometimes be mislead-

ing, as illustrated in Fig.

14.16

. In a SAGD well both DTS and thermocouple (TC)

temperature measurements are available. There are three TC measurements avail-

able along the horizontal portion of the well marked on the figure with red dots.

Taken on their own they suggest a temperature gradient as shown by the straight red

line. However a DTS continuous temperature profile paints a different picture as

shown by the continuous blue line. The black line shows the wellbore path (chang-

ing from vertical to horizontal going from left to right).

Fig. 14.16

DTS vs. TC temperature distribution in a SAGD well. Courtesy SPE 117206

Bibliography

Feng M, Lufan Z, Michio I. Detection of ceramic cracks using a distributed high-resolution

Brillouin fiber optic sensor. SICE J Control Meas Syst Integrat. 2010;3(4):279-84.

Holley EH, et al. Interpreting uncemented multistage hydraulic-fracturing completion effective-

ness by use of fiber-optic DTS injection data. SPE Drill Completion. 2013;28(03):243-53.

Holley EH, et al. Integrated analysis combining microseismic mapping and fiber-optic distributed

temperature sensing (DTS). In: Paper 136565 presented at the Canadian unconventional

resources & international petroleum conference, Calgary, Alberta, Canada; 19-21 Oct 2010.

Search WWH ::

Custom Search