Environmental Engineering Reference

In-Depth Information

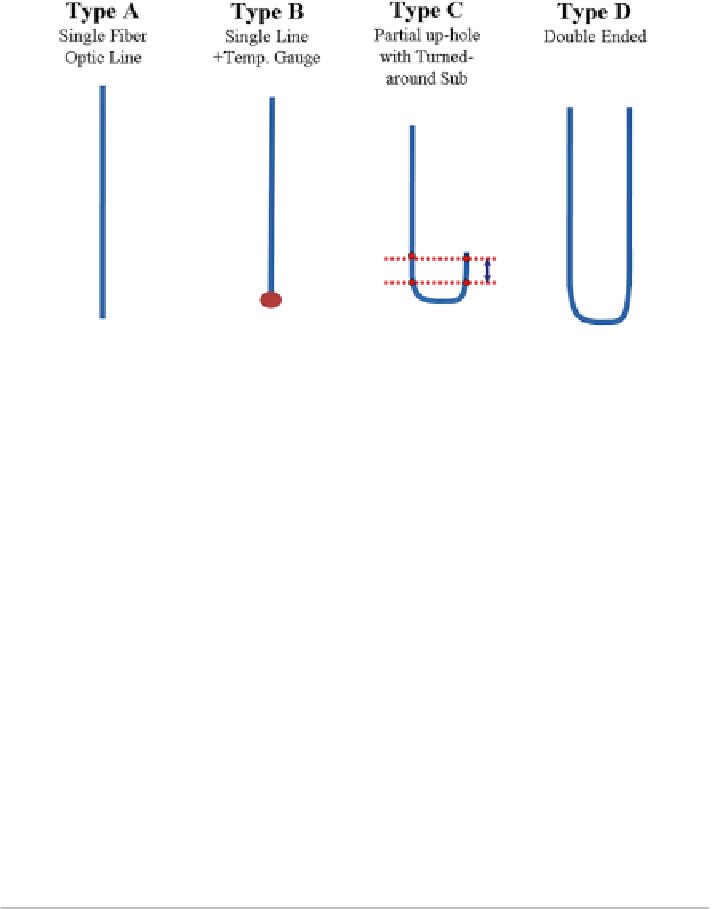

Fig. 14.6

Single and double installation modes. After Mehdi Shahri

DTS installation type D has the advantage that if the fiber breaks the system still

works. It also allows for easy calibration even if the attenuation is not linear.

However this kind of installation is more costly and the fiber may become damaged

if it does not have sufficient protection.

Whatever the installation type there are some mechanical considerations that

need to be taken into account. For example when “pushing” a fiber optic cable down

tubing it may coil up producing an “over stuff”. This may amount to as much as 3 %

of the total cable length and may lead to inaccurate depth measurements. The “over-

stuff” effect is lesser in smaller tubing sizes. A secondary effect is actual cable

stretch under its own weight, much in the way that conventional wireline logging

cables stretch when lowered into a well. However in the case of fiber optic cables

this is less than 1 % in wells less than 15,000 ft deep.

DTS measurements which are based on the Raman scattering phenomenon are

intensity based. In other words, they require calibrations where there is sensitivity

to changes in wave attenuation. DAS measurements however are based on Brillouin

scattering which is frequency based and is not sensitive to attenuation. So, once the

DAS system is calibrated after setup, there is no extra calibration required.

DTS Applications

Real-time monitoring of completion operations is particularly useful in multistage

fracking jobs. The presence of a DTS system in a new well allows continuous moni-

toring of the placement (or non-placement) of frac fluids and proppants via detailed

sensing of temperature variations in both the time and depth domains. Figure

14.7

illustrates the first stage of a fracturing operation. The cooling is occurring at depth

interval from 9,390 to 9,450 ft. The perforations are at 9,432-9,442 ft. This confirms

that the colder injection fluid (compared to ambient reservoir temperature) is flow-

ing into the desired perforations.

Search WWH ::

Custom Search