Environmental Engineering Reference

In-Depth Information

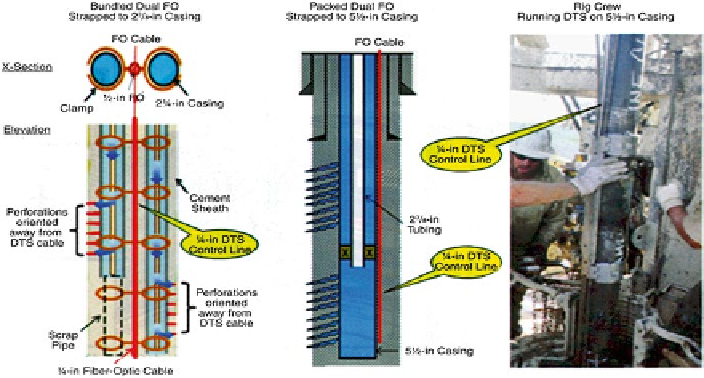

Fig. 14.5

DTS fiber deployment in different casing configurations. Courtesy SPE 163694

Types of DTS/DAS Installations

Essentially a fiber optic cable may be installed in a well either permanently, semi-

permanently, or retrievably. In a permanent installation an armored cable is run

outside the casing, strapped in place and cemented along with the casing. This

method is only possible with new wells but it is applicable for vertical, deviated,

and/or horizontal wells. Besides fiber optic lines, there will be a permanent magnet

rod running inside the jacket of the armored cable. The magnetic rod is used to

locate the optic fiber and allow a perforating gun to be oriented so as to avoid dam-

aging the fiber optic cable.

In a semi-permanent installation, the fiber optic cable is pushed through the well

and has the advantage that it can later be replaced if necessary. In a vertical well

typically the cable is fed through the tubing. In deviated or horizontal wells a pro-

tected fiber optic cable is run built into coiled tubing.

Cables can be run in either single or double mode as illustrated in Fig.

14.6

.

Type A and B involve a single line, which cannot be calibrated to accurate tem-

perature although very small temperature changes can be detected without

knowing the absolute value. The resolution is as high as other types and can

detect to within 0.1 ᄚF. The pressure gauge in type B is a solar optic pressure

gauge which works based on displacement of a diaphragm at different optical

frequency. The displacement with time is then converted to pressure. DTS

installation Type C allows for calibration via two temperature readings at the

same depth.

Search WWH ::

Custom Search