Environmental Engineering Reference

In-Depth Information

on each size of caliper insures detection of even very small irregularities in the tubing

wall. In pumping wells, the tubing caliper log may be run by a single operator without

the need for a pulling unit crew to be present. A “pullsheet” showing the maximum

percentage of wall loss of every joint of tubing in the wall may be prepared. Before the

well is pulled, a program for rearranging the tubing string can be provided. Moving

partially worn joints nearer the surface and discarding thin-wall joints substantially

prolong the effective life of tubing strings and reduce pulling costs in pumping wells.

In fl owing or gas-lift wells, the tubing-profi le caliper provides an economical method

to periodically check for corrosion damage, monitor the effectiveness of a corrosion

inhibitor program, or detect damaged tubing joints when “working over” a well.

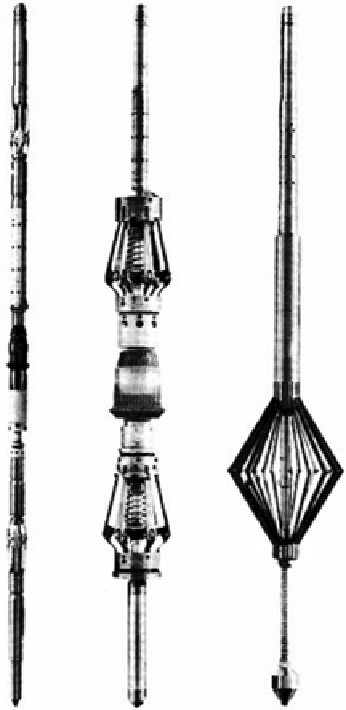

Fig. 13.1

Casing and

tubing-profi le caliper tools.

Courtesy the DIA-LOG

Company

An accessory tool, which may be run in combination with the tubing-profi le cali-

per, is the Split Detector. This tool, functioning much like a magnetic collar locator,

is designed to detect and log vertical splits or hairline cracks in the tubing that might

be diffi cult to locate with the profi le caliper. In practice, the split detector is used to

log down the tubing, and the profi le caliper to log up the tubing. This gives a

Search WWH ::

Custom Search