Environmental Engineering Reference

In-Depth Information

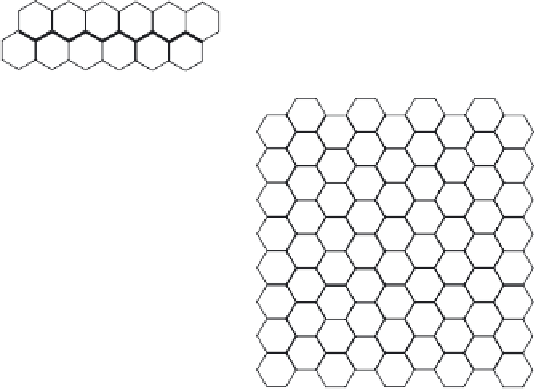

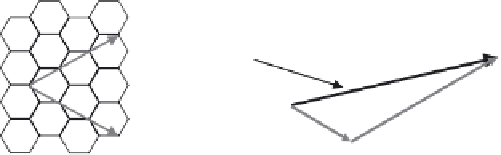

Axis of tube

Zig Zag tube C

(7,0)

Chiral tube

C

(5,2)

a

1

a

2

na

1

ma

2

Basic Vector system

Armchair Tube C

(4,4)

Axis of

tube

2D Graphene sheet

Figure 2.18

The labelling of different forms of carbon nanotubes using the vector system.

or either end or open at one end and blocked with a metal nanoparticle at the

other. The carbon nanotubes themselves may take a range of forms and are usually

termed as C

(n,m)

tubes. The numbers in the name refer to the helicity of the tube

(Figure 2.18), two special cases being armchair [4,4] and zigzag [7,0] tubes. This

results in a range of properties ranging from conductive to semiconducting proper-

ties. There is still a signifi cant challenge in preparing any single form of nanotube

by design and therefore most samples contain many different forms.

Carbon nanotubes can be prepared by similar methods to those used to prepare

C

60

by simply varying the pressure of argon in the reaction atmosphere. However,

control of carbon nanotube growth had been a particular challenge, along with the

drive to fi nd a cheap and scaleable method for their preparation. Recently the use

of chemical vapour deposition (CVD) based methods has allowed the preparation

of carbon nanotubes of both multi and single walled types by careful deposition of

metal particles on a surface. The vapour- liquid -solid (VLS) method allows the

preparation of long carbon nanotubes attached to a surface. Typically, a surface is

coated with nanoparticles of a suitable metal, such as gold, and a vapour of argon

containing a suitable carbon source, such as carbon monoxide or ethylene, is then

passed over the substrate whilst it is heated to high temperatures. The metal

nanoparticles melt and act as nucleation sites for the formation of the carbon

nanotubes. The initial carbon is dissolved in the metal droplets and begins to form

a graphite - like fi lm. The fi lm becomes insoluble in the metal droplet and partitions

Search WWH ::

Custom Search