Environmental Engineering Reference

In-Depth Information

Film thickness

Film thickness

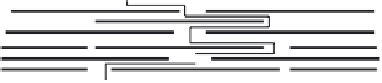

Figure 2.13

The diffusion pathway though a polymer fi lm (top) and polymer nanocompos-

ite fi lm (bottom). The clay nanoplates in the composite fi lm prevent direct diffusion, so forcing

the gas molecules to take a more indirect route through the fi lm.

is possible to prepare a conducting fi lm of silver by simple evaporation of an ink

or paint to leave a fi lm of nanoparticles in contact with each other. However, to

prepare well defi ned, defect free tracks the coating on the nanoparticles and the

solvent in which they are suspended must be removed. This is often done using a

low temperature post treatment. The nanoparticles processed in this manner are

generally considered to be immobilised on the surface of the substrate.

2.4.7.3

Processing

Perhaps one of the major reasons that nanoparticulate materials have received so

much commercial attention is their ability to be processed in novel ways compared

to the bulk material. This is particularly the case for nanoparticles of inorganic

materials. The particle form lends itself well to dispersion in a range of solvents or

to incorporation into a polymer. This means that low temperature processing

methods may be used to prepare devices. Furthermore, the ability of an agglomer-

ated fi lm of nanoparticles to form a continuous fi lm with properties similar to that

of the bulk material means that nanoparticles may be used to prepare components

which would ordinarily rely on vapour deposition technology and lithography.

Some examples of how nanoparticle technology could and is replacing other

methods of materials manufacture is discussed.

Silver i nk

Conductive tracks for use in antenna and printed circuit board manufacture are

typically manufactured using subtractive or additive processing techniques. There

are two common ' subtractive ' methods (methods that remove copper) used for the

production of printed circuit boards, silk screen printing and photolithography. The

vast majority of printed circuit boards are made using this method by bonding a

layer of copper over the entire substrate, sometimes on both sides (creating a ' blank

printed circuit board'), then removing unwanted copper after applying a temporary

mask (e.g. by etching), leaving only the desired copper traces. In the ' additive '

processes a catalytic seed layer is deposited upon a surface and the metal, typically

Search WWH ::

Custom Search